Ten Years of Reliability Your Trusted Partner

1. Introduction To The Main Assembly Of Semi Trailer

5. Semi Trailer Inspection And Maintenance

6. Container And Tire Maintenance

7. Truck Maintenance Guides in Different Seasons

8. Vehicle Maintenance Knowledge In Winter

During transportation, safety is always the top priority for truck drivers! If renting a trailer is to save worry, then the maintenance of the trailer is to maintain life. Check that there are no problems before driving, and then you can go on the road.

Based on the rich practical experience of market service professionals, we are here to summarize the use of semi trailer, semi trailer maintenance, and maintenance knowledge guides for the reference of the majority of drivers.

It is strictly forbidden to weld any part of the main beam without the guidance of professional technician.

Please read the instruction manual carefully and do regular maintenance well.

1, Frequently check whether the trailer tire bolts are loose.

2, Check the suspension every two days and adjust the tie rods to see if the bolts are loose.

3, Ensure the specified tire pressure when driving.

4, Check whether there is air leakage in the air pipe.

5, Regularly check the distance between the traction pin and the center of the semi trailer axle at both ends, the error shall not be more than 1.5mm.

6, Check whether the steel U-bolt is loose every 5000km.

7, The trailer can not be overloaded , unbalanced, or concentrated in the middle of the frame.

8, The spare tire must be fixed tightly and the safety bolts must be locked.

Special reminder

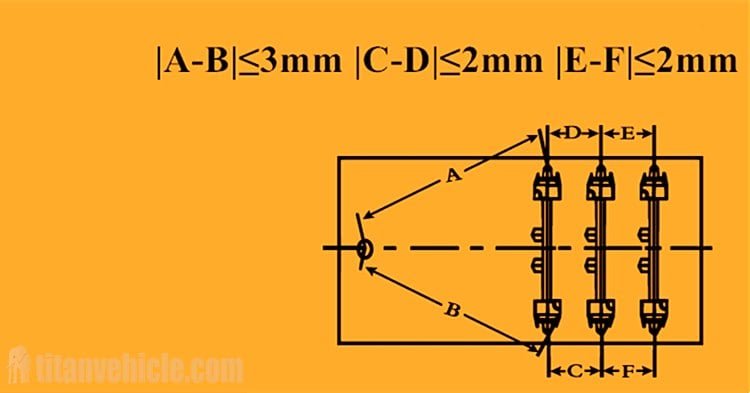

After driving for one month or 5000 kilometers for the first time, the wheelbase should be tested and adjusted according to the picture on the right.

|A-B|≤3mm |C-D|≤2mm |E-F|≤2mm

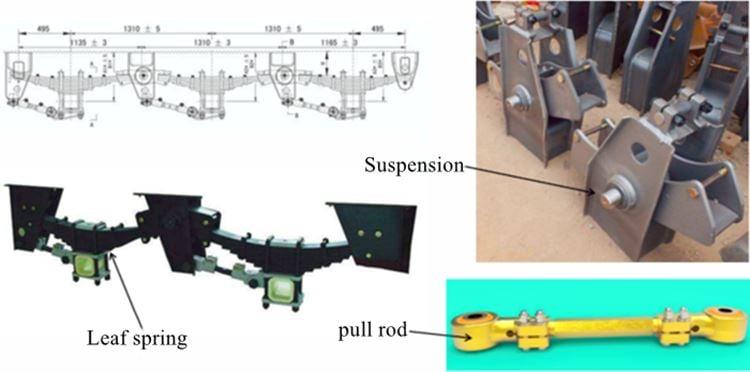

Suspension system (rigidity): Transfer load and absorb vibration.

Axle and wheel hub system: A single, two and three axle assemblies with the same structure are installed under the suspension system. The tire and rim assembly are fastened to the wheel hub with tire bolts to support the weight of the entire vehicle.

Landing leg lifting mechanism: In order to make the semi trailer be able to park reliably after being separated from the tractor, two outriggers, linked or single-acting, are provided at the front end of the frame. It is composed of a screw drive mechanism, a bevel gear drive mechanism, a two-speed reduction box, a transmission rod, and an operating handle.

When the handle is pushed in, it can be raised and lowered at a high speed by turning, and when the handle is pulled out, it can be raised and lowered at a low speed by turning. When the landing legs touch the ground, they can only be raised and lowered in low gear.

Kingpin and guide plate/frame: The lower part of the front end of the frame has a kingpin and a kingpin connecting plate connected to the saddle of the tractor. The kingpin is mainly used to transmit the traction force of the tractor and the braking force during braking.

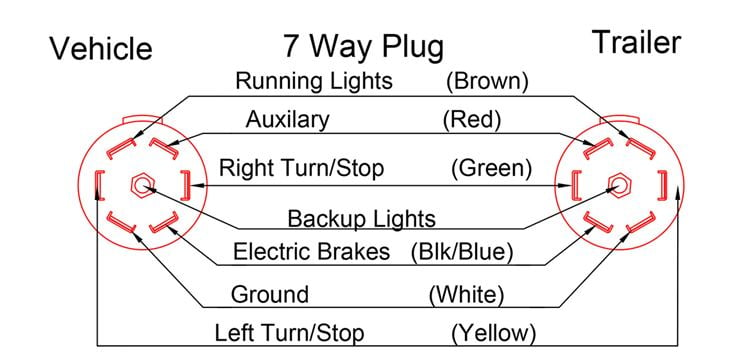

The semi trailer transmits the light signal of the main vehicle to the trailer by connecting the spiral cable plug of the tractor to the circuit socket at the front end of the trailer. Therefore, the vehicle is equipped with an international general electrical system that matches the tractor. The electrical system is generally composed of seven-core sockets, multi-core cables, junction boxes, waterproof connectors, and various lamps and other components.

Seven-core circuit connection diagram:

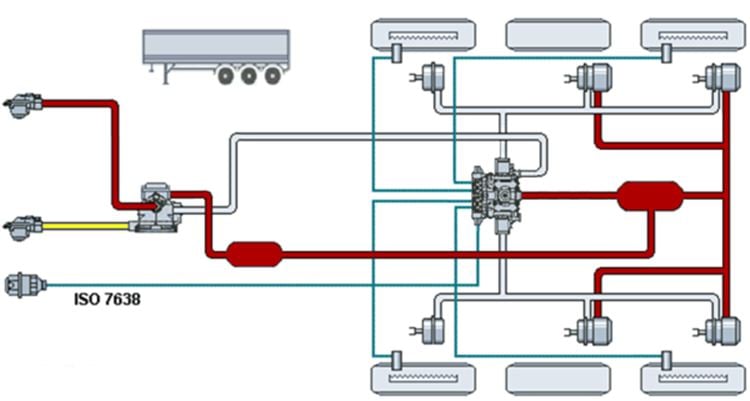

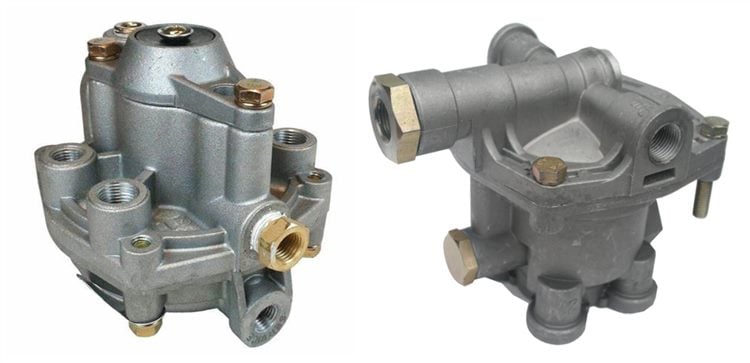

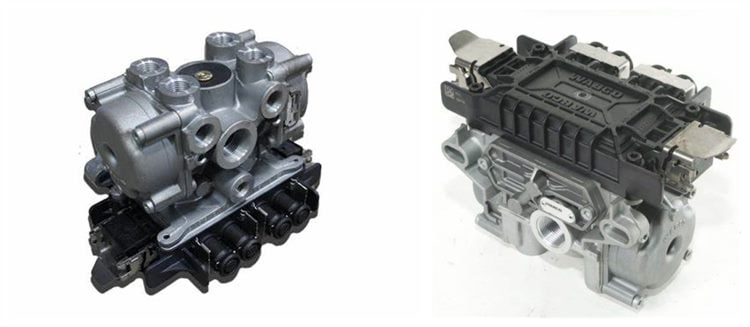

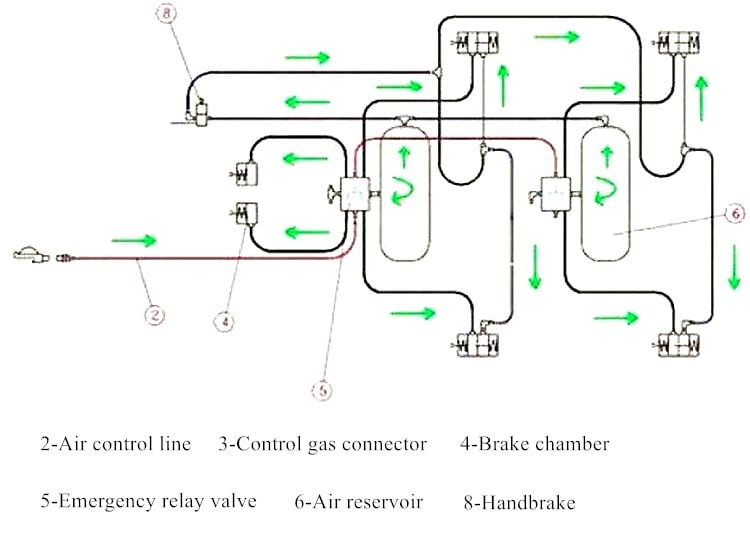

There are three major parts: emergency relay valve, ABS valve, and brake chamber. Most of the faults come from these three parts.

Emergency relay valve: The pneumatic components of the vehicle braking system can realize emergency braking when the semi trailer's inflation pipeline is damaged or the air intake is cut off, shortening the braking lag time and quickly releasing the brake, replacing the original semi trailer system, the brake valve, distribution valve, acceleration valve, and quick release valve in the dynamic system.

ABS (Anti-lock brake system): The electronic control system that monitors and controls the speed of the vehicle during braking, including ABS solenoid valve, ABS wiring harness, ABS probe, gear ring and other components. Cooperate with the relay valve to perform the service brake function; Prevent the brakes from locking, detect the wheel end speed through the probe, when the speed drops to 0, the signal is fed back to the solenoid valve, and the solenoid valve adjusts the air pressure to reduce the braking force and prevent braking lock to increase the driving safety factor.

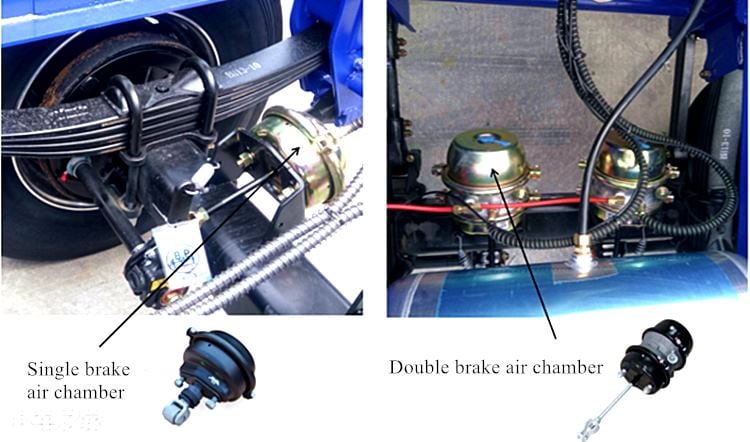

Semi trailer brake chamber

It is composed of the trachea's air pipe joint, inflation pipe, operating pipe, air reservoir, brake chamber, relay valve, ABS valve, ABS sensor and wheel brake. The inflation pipeline is connected to the tractor's air cylinder through a quick pipe joint; the control pipeline is connected to the tractor's brake valve through a quick joint. When the semi trailer brakes, each brake chamber acts at the same time.

Service brake: Generally, service brake (foot brake) is used during driving, which is convenient for decelerating and stopping when moving forward.

Parking brake: The parking brake is the brake used when the car is at a standstill. It is called the parking brake, also known as the "hand brake". Its main function is to prevent the car from sliding forward and backward.

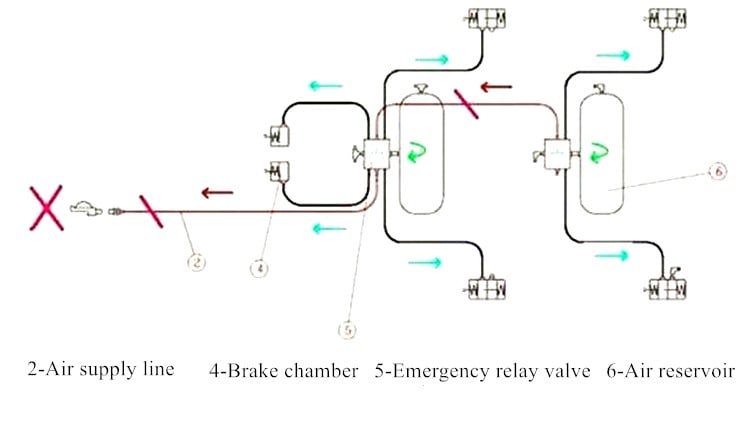

Air-cut brake (emergency brake): The air-filled pipe is cut off or is seriously leaked, and the trailer brake system automatically executes the emergency braking behavior. The control pipe will not be broken, but the "foot brake" will fail.

Importance: When the front air pump is damaged or the inflation tube is disconnected, and the air storage cylinder is seriously leaking, the vehicle's "foot brake" will fail or be ineffective. The air brake is an important guarantee for the safety of vehicles or personnel!

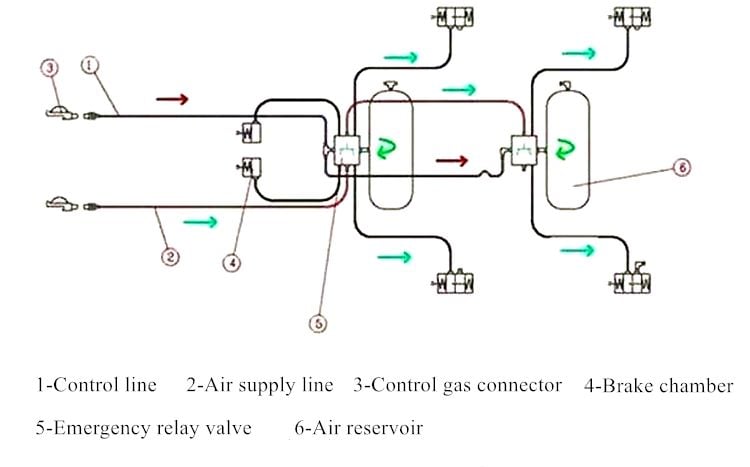

Working braking state in normal braking:

When the brake pedal is stepped on, the control pipeline ① delivers air to the emergency relay valve ⑤, and the emergency relay valve ⑤ controls the ⑥ air reservoir to supply air to the brake cylinder to generate braking force; when the brake pedal is released, the emergency relay is activated, the valve quickly releases the compressed air of each sub-cylinder and quickly releases the brake state.

Feedback braking state during inflation

The trailer parks for a long time. When the brake system has no air pressure, the parking brake system (air brake) works at this time. When the tractor is inflated into the air reservoir of the trailer ⑥ through the gas supply pipeline ②, the emergency relay valve is now in a safe braking state. In the safe state, the emergency relay valve sends the compressed air to each brake cylinder. When the air pressure of the trailer ⑥ air cylinder rises to 4.5 bar, the safe state is released. This function is referred to as feedback braking function. The brake cylinder generates braking force in the inflated state, which is a safety protection function.

Automatic braking state in case of emergency air failure

When ②the air supply pipeline is accidentally damaged during driving, the compressed air in the trailer ⑥the air tank will enter the ④brake cylinder through the ⑤emergency relay valve, and automatically perform braking measures to ensure the safety of the vehicle in emergency situations, which can be used in a short time Drove to the maintenance station, but it won’t last long. When the tractor is stopped and the trailer ② gas supply pipeline needs to be disconnected, the trailer brake cylinder can also be seen to work, which is the same principle.

Vehicles need to do basic inspection and maintenance. Doing a good job in inspection and maintenance that can avoid unnecessary safety hazards and reduce the cost of use.

Semi trailer inspection

Tire: Whether there are cuts, scratches, bulges, tire pattern wear and tire pressure are normal

Axle suspension:

(1) Whether there are cracks in the welding seam of the suspension support

(2) Suspension support and tire bolts are not loose

(3) Ensure that there is no looseness of the U-shaped axle

Rim: Whether there are cracks and deformation

Brake system:

(1) Whether the brake piping system and brake drum are damaged, worn or cracked;

(2) Ensure that the braking is normal without delay;

(3) Check whether the brake air circuit and the emergency relay valve are normal before driving in northern areas in winter;

(4) Whether the desiccant in the drying tank of the main vehicle fails

Supporting device: All parts of the supporting device are intact and can be used for normal lifting and shrinking

Wire harness and trachea: The wiring harness and air pipe are free from cracks, abrasion, or air leakage, and the wiring harness connectors are in good condition

Lamps and labels:

(1) The lamp is intact and lighting clearly visible

(2) The label is clear without falling off and without covering

Kingpin: Whether the wear of the kingpin exceeds the normal value

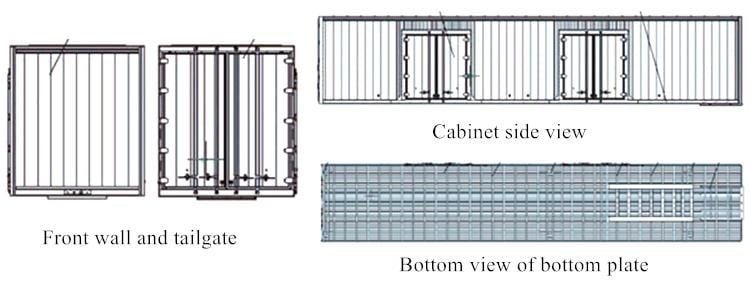

Box body and door:

(1) The box body and the semi trailer locking device are connected in place without loosening

(2) The door lock device can be used normally, and the sealing rubber strip has no aging damage

Other: No loosening of fasteners, no cracks in welds, no obvious wear and aging of rubber parts

Hub maintenance operations: dismantle and inspect the hub system, clean the shaft head and internal and external bearing failure grease, replace with qualified new grease, check whether the bearing wear affects the use, check the performance of brake pads, brake drums, brake pads and other components, according to inspection As a result, maintenance and replacement are carried out.

Cycle:

① BPW shaft maintenance frequency: 120,000-150,000 kilometers.

② VALX axis maintenance frequency: 2 years or 400,000 kilometers (1 year or 200,000 kilometers after maintenance-free).

③BPW 400K/600K: 2 years or 400,000 kilometers/3 years or 600,000 kilometers.

④Fuwa shaft maintenance frequency: 50,000-70,000 kilometers.

Calcium base grease:

Content: Inject or lubricate the semi trailer legs, adjusting arms, camshafts, balance beam pins, leaf springs and other parts with calcium base grease.

Cycle: Regularly used vehicles should be greased once every half a month to a month or vehicles that experience heavy rains also need to be greased once, and less frequently used vehicles need to be greased after being used again. Apply sufficient grease to ensure adequate lubrication and reduce component loss and damage caused by mechanical friction.

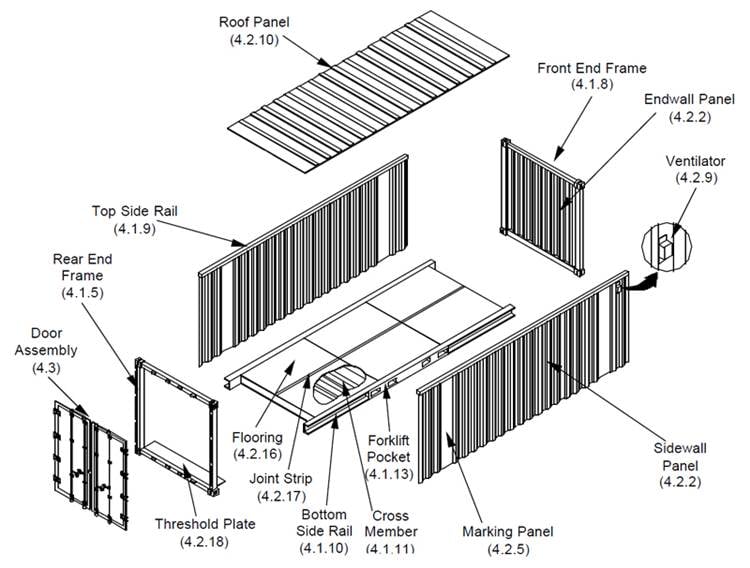

Introduction to the structure of container body:

The structure of the container

Container repair method:

(1) Patch repair: For holes, cracks, etc.

(2) Replacement and maintenance: For large-scale damage and serious deformation.

(3) Scrape putty paint repair: For small deformation and no damage.

(4) Adhesive repair: For cracks, composite board cabinets are common.

(5) Liner welding: Cracking and welding.

(6) Sheet metal correction: For deformation and bending, such as hinges, locks, etc.

(7) Gluing and sealing: Rain leakage and water leakage on the top or side panels.

(8) Steel reinforcement: Aiming at the overall deformation of the composite board, box expansion, etc.

Tire maintenance

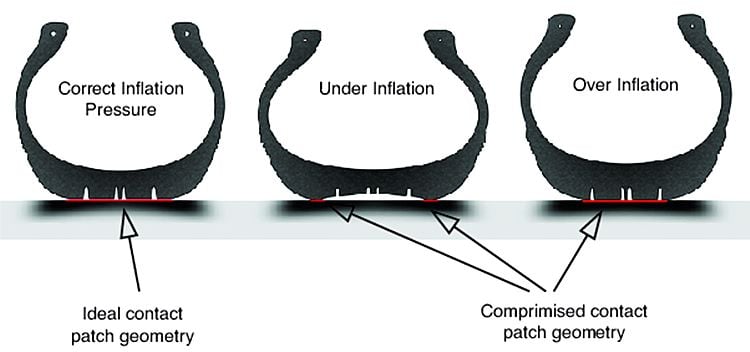

The influence of tire pressure

Market service experts will share trailer-related knowledge and maintenance precautions for drivers from time to time, hoping to help everyone, safety first.

1. Truck interior cleaning

After a rainy and scorching summer, a lot of bacteria will grow in the vehiclepet, floor glue and other corners. In the autumn, the weather becomes cold, the windows of the vehicle will not be opened frequently, the air in the vehicle will start to become turbid, and the peculiar smell and bacteria will pose a hazard to human health. You should immediately do a thorough interior sterilization and cleaning for your vehicle.

2. Brake system detection

Pay attention to whether the brake fluid is sufficient and the quality has deteriorated. If necessary, add or replace it in time. At the same time, pay attention to whether the brake is weakened or deviated, the pedal force of the brake pedal and the wheel lock point during braking If necessary, clean the pipeline part of the entire brake system.

3. Maintenance of the charging system

It is important to check whether the generator belt is aging or cracked after the rainy season or high temperature weather. If the above situation does not happen, remember to check the tightness of the belt. If the belt is too loose, it will cause the belt to scream, make the belt wear early, and the belt will be too tight, and it will cause the partial wear of the generator bearing.

4. Change the antifreeze

The weather turns cooler in autumn. Once the cold air arrives, it is likely to affect the normal operation of the vehicle's cooling system.

5. Truck tire maintenance

Because of the high temperature in summer, the tires generally cannot be too inflated. It's different in autumn. Because the temperature is relatively low, the tires need to be supplemented with air pressure to reach the specified range. At the same time, check the tires for obvious injuries, scratches, etc. In autumn and winter, the rubber becomes harder and relatively brittle, which not only reduces the friction coefficient, but is also easier to leak air and puncture tires.

6. Maintenance of heating pipe and fan

In autumn, the weather gets colder and hoarfrost will appear when the temperature is low. In this season, pay special attention to whether the wind from the defrosting vent under the windshield is normal and whether the heat is sufficient. If there is a problem, solve it in time, otherwise, it will Your driving causes unsafe factors.

7. Maintenance of the air conditioner

After a lot of rain in summer, vehicles often walk on some wading roads, and the lower part of the condenser of the air conditioner is inevitably contaminated with sand. Over time, a large amount of silt and dust will accumulate, which will seriously affect the service life of the air conditioner. Therefore, it is very necessary to check and maintain the operating condition of the air conditioner when autumn comes. In addition, the vehicle water tank is also easy to be contaminated with sand. This must also be noted. Once the vehicle water tank is found to have sedimentation, it should be cleaned immediately.

Common sense of vehicle maintenance quick battle to quickly resolve emergencies in winter

1. After it snows, there will be a lot of snow on the vehicle body like the road. If it is not cleaned up in time, it will seriously affect the driving safety. Therefore, put the unused newspapers outside the windshield before snowing, and then use tape to cover it. Fixed so that you won’t be bothered by frost and icing on the windshield the next morning.

2. In winter, the temperature is very low, remember not to wipe the windows with a wet cloth, otherwise it will easily freeze the windows, and the more you wipe them, the more flowers, so it is best to use a dry cloth when wiping, or bring your own dry cloth in the vehicle. cloth.

3. In winter, the keyhole of the vehicle door is easy to freeze due to water or water, so the keyhole should be wiped frequently, and a little lubricating oil can be injected into the keyhole. Remember to wipe the water around the door, otherwise it will be opened the next day It's troublesome not to open the door.

4. The temperature in winter is low, and the glass of the vehicle is easy to freeze and frost when driving on the road, so open the door for a few minutes before driving, and let the temperature in the vehicle be similar to the outdoor when driving on the road or locking the vehicle.

Prevention of common sense vehicle maintenance in winter

1. Waxing in early winter is the best time to maintain the paint, because the number of vehicle washes after winter will be significantly reduced, and the vehicle body is not easy to get water after waxing, so the possibility of freezing is reduced.

2. In winter, wheels and tires will become hard and brittle, and the safety factor will be greatly reduced. Therefore, in winter, you should always clean up the debris in the tire pattern and avoid using tires that have been repaired more than once.

3. In winter, you must use a professional glass cleaning fluid, otherwise it will be counterproductive, but you can also add alcohol or white wine to the water to lower the freezing point.

4. The winter oil must be used, otherwise it will cause engine failure.

5. The amount of antifreeze should be appropriate, and the mixed antifreeze that has been used for more than two years and used for more than one year must be replaced. It is best not to mix antifreeze.

6. Check whether the brake fluid is sufficient, whether the quality has deteriorated, and if necessary, it should be replaced and added in time.

7. Check whether the electrolyte in the battery is sufficient. If the battery is not charged enough, it is easy to rupture in the severe cold.

Mastering the above vehicle season maintenance guide, coupled with the usual vehiclee for the details of the vehicle, will surely allow you and your vehicle to have a worry-free ride in any environment.