Ten Years of Reliability Your Trusted Partner

A modular trailer accounts for various special trailers or semi-trailers that are normally used in the transportation of bulky and heavy cargoes that cannot easily be disassembled for ease of transportation.

Modular trailers are commonly used in the chemical industry, power stations, construction industry and in the iron and steel industry. Due to their excellent lateral stability, they can be used for mining operations. They are also used to transport products that are over-length. The tractor trucks are used to provide traction for the modular trailers.

The loading platform of all modular trailers is usually kept at a balanced position during the transportation of products on rugged surfaces due to their excellent dumping characteristics. The brace kit of the modular trailer vehicle can attain either 3 or 4 brace points that make sure that there is a uniform loading on each point.

TITAN Hydraulic platform trailer for transport oversize and over weight freights that split apart series hydraulic full trailer that can be assembled into weight from 45 tons to 2200 tons of various series.

150-250 tons hydraulic multi axle trailer

A Self-propelled modular transporter (SPMT) is a platform vehicle consisting of a large arrangement of wheels. It is also known as a self-propelled modular trailer.

These types of vehicles are basically used for the transportation of heavyweight and bulky objects such as industrial equipment and project parts such as huge bridge sections among others that cannot be handled safely through the use of conventional trucks.

The heavy haulers can be coupled together to increase their capacity. Hence, they can transport wide and long construction equipment. Another reason why SPMTs are widely used in construction plants is that they enable builders to increase their efficiency and reduce overall costs.

- Extremely robust and durable construction, extremely high load capacity.

- Platform height is adjustable

- All wheels can be steerable

- Small turning radius, 48° steering angle with hydraulic gooseneck

- Longitudinal and lateral combination of each module are available

- All wheels steerable automatically or manually.

- Hydraulic axle suspension system adopt uneven road condition.

- Lifting cylinder make multi axle low bed trailer automatically responds tough road conditions.

- Dual-circuit hydraulic system guarantee safe work condition

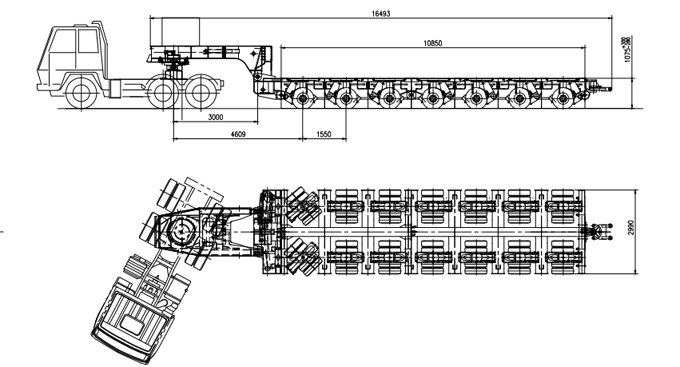

Drawing of self propelled modular transporter for sale

1. Meeting Different demands

Due to the modularization nature of the multi axle trailer, various cargo demands can be met.

These multi axle trailers are completely modular and that means they can be connected to each other either end to end or side by side to provide various configurations for use as the cargo would require. The end to end or side by side connection is made possible through a mechanical coupling or in some cases, loose coupling.

There is a single set of controls for each modular transporter that can be synchronized for coordinated steering function and other operations as well. These capabilities make it possible for the loading and transportation of a complex and oversized project cargo.

2. High Load Carrying Capacity

This is arguably the most defining characteristic of a modular trailer that makes it an appropriate vehicle for the project cargo. Its usefulness begins here – its ability to take up the load.

The main load-bearing frame and the suspension are constructed of 690 MPa yield stress steel material. Ideally, this is the main structure for bearing, taking into consideration the most dangerous cargo condition.The entire frame has a strong strength and great capabilities able to efficiently withstand bending moments in case of concentrated loads.

Multi truck head traction and pushing transport

3. Efficient Transportation

The modular trailer offers effective transportation means a for a project cargo with reliable speeds.

The design and building of a multi axle trailer are such that all the axles can swivel through 270°. In some cases, you can even find some that can go up to 360° full motion. Looking that the bulky size of the project cargo, features of maneuverability as present in the modular trailer are very useful.

Each of these axles is usually controlled via a system of controls to facilitate the turning of a modular trailer. A number of motions can be executed on the multi axle trailer including allowing it to spin on one location or else move sideways as needed in a specific condition.

Efficiency in transportation is also enhanced through stable operations. Each of the modular trailer units can be categorized into 3 and 4 hydraulic regions. All the fields can maintain hydraulic pressure to the axles in it. This enables the trailer to make desired adjustments for uneven terrain ensuring the stability of your cargo during transportation. The low loading height of the transporter coupled with a wide wheel track ensures a greatly enhanced stability too.

4. Safety

Due to its huge size and weight, the project cargo needs careful attention to its safety during loading, transportation and offloading.

This is what the modular trailer has been designed for. It is very good in keeping the cargo in a horizontal balanced position offering 3 and 4 points of support that take uniform loading forces.

The modular unit uses a hydraulic wheel bogie that comprises a bogie frame, hydraulic cylinder, rocker arm, the tyre and axle that are designed for robust load capacity needs.

The hydraulic modular trailer stability is important when transporting heavy cargo for various reasons. Stability reduces the risks of accidents, which leads to injuries to people.

Accidents also damage the environment and the equipment or cargo in transit. Accidents create additional costs because projects are delayed. The equipment must be replaced or repaired before it can be used for construction.

Most of the accidents are caused by human error and not mechanical failure. When handlers are not properly trained, they do not load the cargo properly on the hydraulic multi axle trailer.

Each modular transporter has a maximum loading capacity. The manufacturer specifies this loading capacity. Loading hydraulic multi axle trailer with an equipment or cargo that exceeds this capacity will cause it to topple off the platform.

Another reason is loading equipment that is too tall for the multi axle trailer platform. Tall equipment requires a wide surface to stay balanced on the road. Hence, the best way to transport such cargo is couple several SPMTs to accommodate the weight of the equipment.

Heavy-cargo transport:

Some companies specialize in transporting heavy cargo from one destination to another. Such companies serve clients who need to transport heavy loads a few times in a year.

The manufacturers also require transport solutions to transport the fully-assembled equipment to the clients or warehouse. The goldhofer multi axle trailer can be customized to transport any cargo as long as it is well packaged.

Construction Industry

The construction of bridges, large buildings and roads also require the use of modular trailers. Big bridge segments and large girders are placed onto the modular trailers from the construction sites.

Construction companies usually have projects located in different areas. Modular hydraulic trailer help in the transportation of the already built sections to places where they will be installed and at the same time shift materials and equipment from one project to another.

self propelled modular transporter for sale

Ship Building Industry

Ships and ship sections are normally huge and bulky. You can imagine how the construction of the big ships you see transporting goods and people across seas is done.

Modular trailers become very useful in the movement of ship sections to assembly halls and the entire ship to the sea. Ships are normally very heavy weighing up to thousands of tones.

The biggest ships will need goldhofer spmt with over 200 axle lines. On some occasions, the placement of the axles is done side by side to help in carrying long and wide ship sections.

Chemical industry construction:

The chemical industry also requires special transportation goldhofer modular trailer to move heavy raw materials, equipment, and finished products.

Setting up the manufacturing sites requires the companies to transport heavy and long tubes, cylindrical tanks, and metallic beams among other parts. In most cases, the parts are purchases from other assembly companies and transported to the chemical production sites.

heavy equipment transport trailer

Mechanical steering axles

When gooseneck steering, the system will control the rods and support arm to steer the tires. This is the type to go for on economic grounds and again to enjoy a long service life.

It comes with low maintenance costs and most importantly, it is highly available.

Hydraulic steering axles

Self propelled modular transporter for sale offers a larger steering angle of up to 65°. Most importantly, it has a higher capacity compared to other options out there.

Steering Operations

The multi axles trailer has many axles even up to 10 axles. So, the multi axles Modular Trailer’s axles need to be steered by either self-steering or automatic steering. Steering without wheels causes serious wearing.

In order to minimize the tear and wear on the tires and the modular hydraulic trailer chassis stress, it is advisable to let the Modular Trailer wheels to accurately follow the towing vehicle wheels regardless of whether it is on a tractor or a lorry.

For this to be achieved, it is normally important that successive wheel pairs take up slightly varying angles and positions under the goldhofer multi axle trailer chassis.

Conventional steering systems for trailers make use of the bogie system for steering through means where both the wheels of a pair get turned concurrently through the changing axle angle where the axle links up the wheels together.

The goldhofer multi axle trailer can get signal when gooseneck or drawbar steering, the axles will be controlled by PPU automatically, you can also use the remote control to steer all axles.

Hydraulic used SPMT for sale

1. The tractor has sufficient power

The maximum driving force of the tractor wheels determined by the engine torque and transmission ratio should be greater than the driving resistance of the vehicle group;

2. The drive wheels of the tractor have sufficient adhesion.

The main determinant of adhesion is the axle load quality of the tractor, which is applied in the form of counterweight in engineering. In order to meet the basic conditions for the driving of a used SPMT for sale, the tractor should have enough weight so that the driving wheels of the tractor do not slip on the road when driving.

The selection of the tractor is considered from these two aspects. First, the maximum driving force of the wheel determined by the engine of the tractor is calculated, and then the driving resistance of the vehicle group is calculated, and compared with the maximum driving force of the wheel, if the driving resistance is greater than the maximum driving force of the wheel, The tractor's capacity is insufficient, you must replace the tractor or increase the number of tractors; if the driving resistance is less than the maximum driving force of the wheel, then check whether the driving wheel has sufficient adhesion according to the given road conditions. If the adhesion is not enough, the calculation must be Increase the counterweight, and finally check whether the tonnage of the counterweight is within the carrying capacity of the tractor. If the tonnage of the counterweight exceeds the carrying capacity of the tractor, you must still replace the tractor or increase the number of tractors. If the tonnage of the counterweight is in towing Within the carrying capacity of the used spmt for sale, a selection report is made.

goldhofer modular trailer for sale

3. Trailer model and trailer structure

The structure of the modular hydraulic trailer is very complicated, and its longitudinal direction is very long. The main longitudinal beam is designed on the trailer to bear the load of the cargo and the supporting force of the tire, forming a beam member in material mechanics. If the cargo is too heavy-weight, the huge bending stress may easily cause the main beam of the goldhofer modular trailer to deform too much or exceed the stress limit, and the main beam of the multi axle low bed trailer may yield or even break; and the bending moment of each splicing part of the trailer body exceeds the allowable At the moment of bending, the joint of the trailer longitudinal beam will become a hidden danger.

Therefore, in the pre-selection of the Multi Axles Modular Trailer model and the pre-loading of the cargo, in order to ensure the safety of the multi axle trailer and the cargo, it is very important to check the force deformation and bending moment of the modular hydraulic trailer. Only the multi axle low bed trailer that have passed all the checks can ensure safe use.

Welcome to leave your inquiry!

We will meet the acme of perfection to serve and provide more details, price, catalog, drawing, videos for you!