Ten Years of Reliability Your Trusted Partner

|

|

|

| Windmill Blade Adapter for Sale | Wind Blade Adapter | Windmill Blade Transport Adaptor |

1. Different transportation methods of wind turbine blade

2. Design of the wiwindmill blade adapter

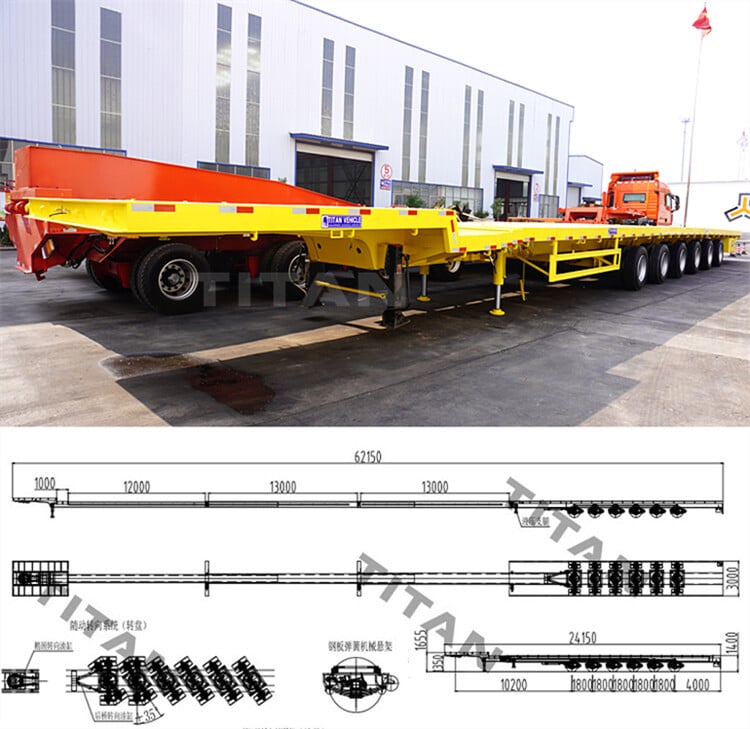

This mode of transportation generally uses ordinary extendable trailers to transport fan blades. The feature of this vehicle is that it can be longitudinally extended to adapt to the transportation of blades of different lengths. It can be directly transported from the manufacturer to the fan station, but it is difficult to turn due to the long turn of the vehicle.

Ordinary 4 Axle Extendable Trailer for Wind Turbine Blades Transportation

Ordinary 6 Axle Extendable Trailer for Wind Turbine Blades Transportation

This mode of transportation generally uses a special blade transport vehicle (windmill blade adapter) with blade lifting-rotating-hydraulic rear wheel steering. The special vehicle can lift the blades through hydraulic control during driving, and rotate 360 degrees by itself, avoiding various restrictive obstacles (mountain slopes, trees, houses, bridges, tunnels, etc.) during transportation, thereby greatly reducing blades The overall length of the transport body improves the performance of cornering.

Windmill Blade Adapter

(1) The advantages of special vehicle (rotor blade adapter) transportation compared with ordinary flatbed vehicle transportation

When the blade length is 51m and the height is 35°, the non-interference height is 32.28m, and the area is 641㎡; while the horizontal transportation is only 2m without interference, the area is 62.6m³; the area of the renovation project involved in the curve is reduced by 10 times.

Transporting the blades by lifting can better avoid high mountains and cliffs, or houses and buildings, so as to realize the rapid transportation of blades. At the same time, this method can also reduce the cost of road reconstruction and house demolition, and help improve the efficiency of blade transportation and engineering benefits.

(2) The disadvantages of special vehicle (windmill blade transport adaptor) transport compared to ordinary flatbed transport

Due to the restrictions of expressways and most grade roads, wind turbine equipment can only be transported by ordinary flatbed trucks on the national public transportation network. Therefore, when mountain wind farms use special vehicles for transportation, it is necessary to choose a suitable location near the wind farm area to set up a midway transfer site. With reference to previous mountain wind power projects, if a wind farm with an installed capacity of 50MW uses special transportation, the transportation cost will need to be increased by about 3.5 million yuan. After the blade is lifted, the height increases to more than 30m, which will increase the net height requirements along the line. Compared with ordinary flatbed truck transportation, it will increase the removal of height-restricted objects (such as crossing highway cables, pipes, branches, etc.). Secondly, since the center of gravity of the vehicle rises after the blade is lifted, which is not conducive to the stability of transportation, it is necessary to place a counterweight at the front of the vehicle, and at the same time, avoid transportation in strong winds.

Wind Blade Adapter/Wind Blade Lifter Adaptor

The length of the wind blade is at least 30 meters, so the above-mentioned transportation method cannot be used in mountainous areas. What should I do? Recently, we saw a semi-trailer specially designed to transport wind blades, which solves the problem of transportation in the mountainous area of wind blades. It is different from the transportation on the car, which is similar to holding a big sword in hand. , The wind blade can be moved up and down, left and right in different directions, so as to avoid various obstacles on the mountain road to meet the needs of wind blade transportation.

Two parts of the wind blade trailer

On the fixed base of the blades, the low center of gravity ensures safety

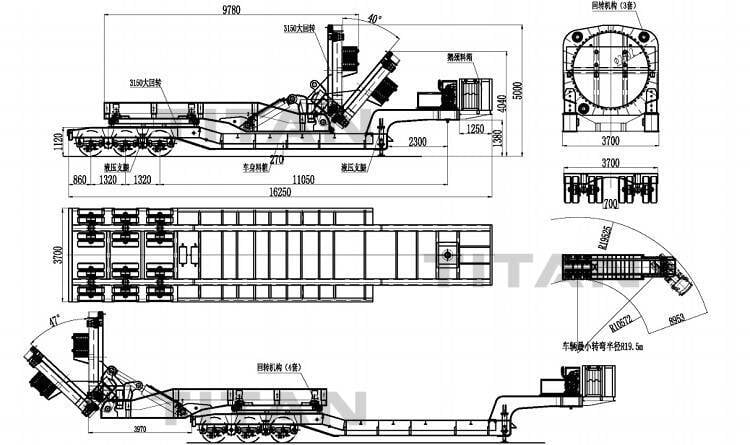

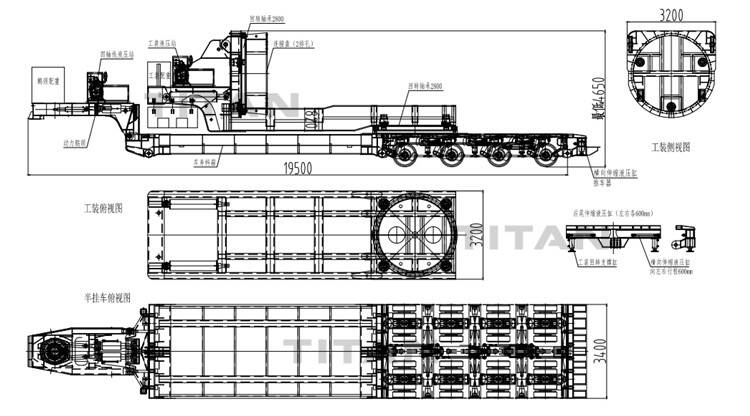

Today, the wind blade adaptor we are going to tell you is different from the picture above. The rearward setting makes the length of this wind blade lifter adaptor shorter, which is conducive to driving in mountainous areas; the operation by dedicated personnel is helpful to improve safety.

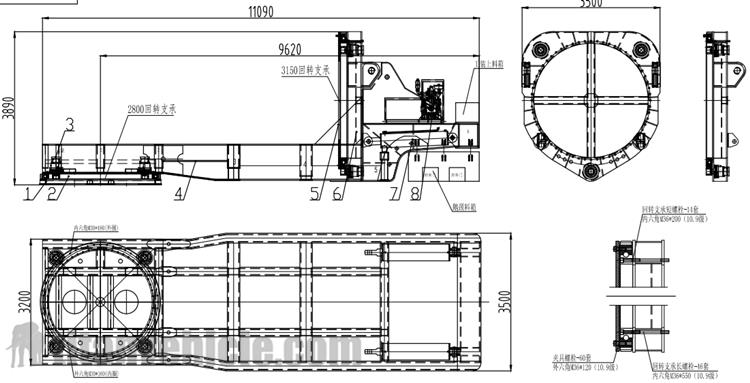

Unlike conventional windmill blade adapter, the length of this wind blade adapter trailer is very short, which is also to satisfy that the vehicle can run normally on mountain roads. You can think of it as a crane, with its walking part on the bottom and a turret on the top. The wind blades are like the boom of this crane.

The wind blades to be transported are fixed on the vehicle by bolts, and the wind blades and the base are firmly integrated. During the transportation process, the wind blades can move up and down, left and right, without danger. The up and down displacement of the base is realized by the oil cylinders arranged on both sides, which can achieve a lifting range of 0-60 degrees. In order to ensure that the center of gravity of the wind blade is unstable when it is displaced, the back of the base can prevent the counterweight to achieve For the balance of the entire vehicle, the counterweight can be flexibly added according to the weight of the wind blade. The trailer is equipped with 275/70R22.5 size tires, the purpose is to reduce the height of the entire vehicle, not only more convenient when loading and unloading, the lower height also ensures the stability of the vehicle during operation.

Inspired by cranes, air conditioning improves comfort

The turret is fixed on the trailer, and the hydraulic motor drives the gear fixed under the turret to realize the rotation of the entire base. The turret can theoretically realize a 360-degree rotation.

If the wind blade is so long, the force generated by the frontal wind is very terrifying, and if it is held high, it is very likely to overturn the wind blade adapter transport vehicle. To solve this problem, the base can rotate along the axis of the blade under the premise of satisfying the lifting requirement, so that the windward side of the blade is always on the side with the smallest area.

A diesel engine is mounted on the wind blade lifter adaptor trailer, and the hydraulic pump directly connected with the rotating shaft provides the power source for the upper part.

The square welded oil tank is used to store hydraulic oil and can provide all heat dissipation capabilities, so there is no radiator installed. The upper part comes with a battery and a fuel tank, and the arrangement of the pipeline is dazzling. It would be better if it can be straightened out. The hydraulic motor that realizes the rotation of the turret and the fuel tank that provides grain for the diesel engine. The entire upper part is operated by a dedicated person, and the operating principle is basically similar to that of a crane. In order to improve the comfort of the operator, an air conditioner is installed in the operating room.

Windmill Blade Adapter Trailer Drawing

4 Line 8 Axle Windmill Blade Transport Adaptor

Wind Blade Lifter Adaptor

1. The cost is high and the project quantity estimation is difficult

(1) Take 25 common domestic mountain wind farms with a total capacity of 50MW as an example. The roads in the site are about 30 kilometers long, and the cost per kilometer is about 1 million yuan, and the cost is about 30 million yuan, which accounts for about the entire wind power. More than 20% of the cost of civil engineering.

(2) Mountain wind farms are complex in topography and geomorphology, resulting in large gaps in the engineering volume of different projects; and due to the requirements of the project investment schedule, bidding and construction are often performed without detailed geological surveys, and the geological conditions are uncertain, making the engineering volume difficult estimate.

2. The technical requirements are more special

(1) During construction: frequent rolling by heavy vehicles. From the perspective of a concrete truck, one of the trucks weighs 17 tons and loads 16 tons, with a total weight of 33 tons. The foundation concrete volume of each machine position of mountain wind farm can reach 300m³-400m³. When pouring the wind turbine foundation, the branch road will be subjected to 30-40 times of repeated rolling by the concrete mixer, while the main road may be rolled 90-120 times. If the road quality is not up to standard, it will cause the road to be crushed.

(2) During equipment transportation: equipment transportation vehicles mainly have the characteristics of ultra-long, ultra-wide, and overweight. For example, when the 2MW unit blade is transported, the distance from the head to the blade tip is more than 50m, and the width of the trailer plate is 3m; when the engine room is transported, the car The total weight is about 100t. These characteristics are different from ordinary roads.

3. The road project for the delayed follow-up project has always been on the critical path of the wind farm project construction plan, and it is also the first project of the project construction. Road construction efficiency and quality are lagging behind follow-up projects such as wind turbines, booster stations, and power collection lines.

1. Road grade

Generally speaking, the roads of mountain wind farms are not high, and the roads of mountain wind farms in my country are generally designed according to the fourth grade or the fourth grade of factory and mine roads. However, in practice, due to the lack of national unified standards, some mountain wind farm road technical indicators require higher than the four-level road standard, and some are lower than the fourth-level road. Based on the research of various aspects of the data, this article believes that it should be implemented with reference to the standards of "Fourth Level of Roads Outside Plants" or "Secondary Arterial Roads on Sites" in the "Code for Design of Factory and Mine Roads". The design speed of mountain wind farm roads is between 15 km/h-20 km/h. If it is to transport heavy, large and special equipment, the design speed can be controlled at 5-10 km/h for safety reasons.

2. Main technical indicators

The technical indicators of wind farm road design can only be determined by reference to the design standards of Grade 4 roads and based on actual transportation conditions. The width of subgrade and road surface is mainly controlled by heavy, large transportation vehicles and hoisting machinery. The width is generally more than 3-4m. Therefore, the minimum width of the carriageway can be 4.5 m, taking into account the mountainous terrain and subgrade reliability, as well as a small number of small vehicles. For the needs of staggered vehicles, 5.0 m is appropriate, and the corresponding subgrade widths are 5.5 m and 6.0 m. In particularly difficult locations,

The straight section can also adopt a subgrade width of 4.5 m, but the wrong lane and warning signs should be set. The radius of the horizontal curve is mainly controlled by the transportation of blades and towers. The minimum radius is related to the width of the road surface and the widening value. The theoretical limit can be about 20 m. In actual work, the transportation of ordinary flatbed trucks is generally considered to be no less than 35 m, the special vehicle transportation consideration department is less than 20m. According to the "Code for Design of Highway Routes", the maximum longitudinal slope of the road should be controlled within 9%; however, according to the specific conditions of mountain wind farms, the longitudinal slope value should be appropriately increased. Generally, the main road should not exceed 14%, in the branch road or local terrain. Restrictions on special road sections can also be appropriately relaxed to 16% or even 18%. At this time, cement concrete pavement should be used to increase the friction of the road surface or auxiliary traction measures should be taken for transportation vehicles to ensure the safety of equipment transportation.

3. Bridge and culvert reinforcement

Reinforcement of bridges and culverts is a common problem in the approach roads of mountain wind farms. Because the roads of mountain wind farms are geographically special, the terrain is complex and diverse, and the original road grades and road conditions are relatively low, various bridge and culvert facilities are not only simple, but also have the problem of disrepair. They must be reinforced to be effective. Satisfy the transportation load demand of the wind farm for heavy parts. When strengthening the road bridges and culverts of mountain wind farms, it is necessary to comprehensively consider major parts

For transportation requirements, scientific design should be carried out based on the structural characteristics, load capacity and disease status of existing bridges and culverts, and the most feasible reinforcement principles and reinforcement schemes should be selected. Mountain wind farm roads can be divided into temporary roads and permanent roads. For bridges and culverts on permanent roads, emphasis should be placed on improving the carrying capacity of their structures; for temporary roads, temporary measures can be taken to disperse the load on the road, or to build temporary access roads and bridges for vehicles to detour. In the specific implementation process, it should be determined based on technical and economic comparison.