Ten Years of Reliability Your Trusted Partner

1. After the bulk cement trailer arrives at the destination, park the cement tanker trailer for sale at the corresponding position of the storage tower, ensure that the discharge hose is vertical to the transport joint of the storage tower, and connect the quick connector of the discharge hose to the storage tower The tower's transmission pipe joints are fastened securely.

2. Check and close the feed port tightly, and close the bulk cement trailer exhaust valve, secondary blowing valve, and unloading valve.

3. Start the power device (diesel engine or power take-off) of the cement tanker trailer for sale to drive the air compressor. Let the air compressor speed reach the rated speed (about 900r/min), and inflate the air into the cement tanker trailer for sale tank.

4. When the pressure value of the bulk cement trailer pressure gauge reaches 0.2Mpa, open the secondary blow valve, clear the pipeline, and then open the cement tanker trailer for sale discharge valve to start unloading.

5. When the pressure gauge of cement tanker trailer for sale drops to 0.02Mpa to 0, cut off the power, stop the operation of the air compressor, close the secondary blowing valve and the unloading valve, open the exhaust valve, and the unloading is completed.

Precautions:

1. When unloading bulk cement trailer, pay attention to the gauge pressure of the pressure gauge. If the gauge pressure exceeds 0.2Mpa, check whether the safety valve of cement tanker trailer for sale is exhausted.

2. The discharge hose shakes greatly when unloading cement tanker trailer for sale. Please close the secondary blow valve half way.

3. When the storage tower is full when unloading cement tanker trailer for sale, first close the unloading valve, then quickly close the power unit, and finally close the secondary blowing valve to avoid pipeline blockage.

4. If the pipe is blocked during the unloading process of the bulk cement trailer, it can be eliminated without stopping the machine. If the discharge valve is blocked, immediately close the discharge valve and air inlet valve. Use the secondary blow valve to eliminate foreign matter in the pipeline. If the bulk cement trailer unloading valve is clogged, fully open the secondary blow valve and repeatedly open and close the unloading valve to eliminate the blockage.

If you have any questions, please contact our staff first to avoid unnecessary trouble for you.

What is Bulk Cement Trailer? - Bulk cement trailer Unloading Operation Method

What is Bulk Cement Trailer? - Bulk cement trailer Unloading Operation Method

Chapter1: About TITAN bulk cement tanker

1.1 What is TITAN powder tanker trailer?

1.2 What are the uses of dry bulk tanker trailer?

1.3 How does cement bulker work?

1.4 TITAN cement bulker transporters demention, drawing and specifications

1.5 Marine transportation of bulk cement trailers for sale

1.6 Feature of the dry bulk trailer

1.7 How to choose specs/capacity of bulk powder tankers?

1.8 Why use pneumatic tanker trailer to transport dry bulk cement?

1.9. How do you use pneumatic trailers?

Chapter2: What is a bulk cement tanker trailer?

2.2 Sealability test of silobas for transportation of powder materials.

2.3 Package and transportation of bulk cement trailers for sale.

2.4 What is the working principle of cement tanker?

2.5 How does dry bulk trailer load powder materials?

2.6 How does pneumatic dry bulk trailer unload powder materials?

2.7 How to maintain cement bulk carrier?

|

The bulk cement tanker trailer are mainly used to transport 30 tons, 40 tons, 45 tons and 80 tons of cement. The main volumes of silo semi trailer are 25 cubic meters powder tanker for sale, 30 cubic meters cement powder truck, 35 cubic meters pneumatic tanker truck, 38 cubic meters bulker truck price, 40 cubic meters cement trailer for sale, 50 cubic meters bulk cement tank semi trailer, 60 cubic meters, and 80 cubic meters.

Powder tanker for sale are V-types silobas and W-shaped dry bulk tanker, and the materials are carbon steel, stainless steel, and aluminum alloy.

Through this video below, you can learn about different types of bulk cement tanker trailers, such as 3 axle dry bulk tanker trailer, 30-ton fly ash tanker, 50cbm cement silo trailer for sale, and process, testing, packaging and customer feedback, etc.

V type cement silo trailer for sale

W shape cement bulker price transporters

W shape cement bulker price transporters

Powder tanker trailer is also called powder material transportation vehicle, which is suitable for bulk transportation of powdered materials with a diameter of less than 0.1mm, such as fly ash, cement, lime powder, ore powder, granular alkali and other particles.

The powder material transportation vehicle is a special-purpose vehicle. Cement bulker trailer is widely used in industry, agriculture, commerce, power plants, construction, etc.

4 axle dry bulk cement tanker manufacturers and 3 axle pneumatic sand trailer

4 axle dry bulk cement tanker manufacturers and 3 axle pneumatic sand trailer

Use the equipped engine or borrow the host to drive the pneumatic dry bulk trailer for sale air compressor through the power take-off drive shaft or pulley, and send the compressed air into the cement bulker for sale air chamber of the sealed pneumatic cement tanker through the pipeline. When the pressure in the cement bulker truck for sale reaches the rated working pressure, open the pneumatic cement tanker discharge butterfly valve, and the powdery material will be discharged through the discharge system.

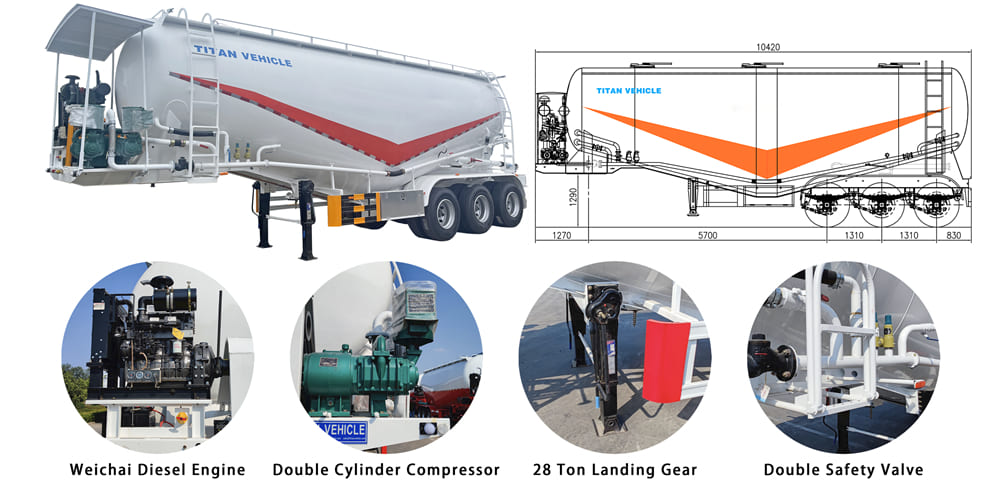

Details of cement powder tankers for sale

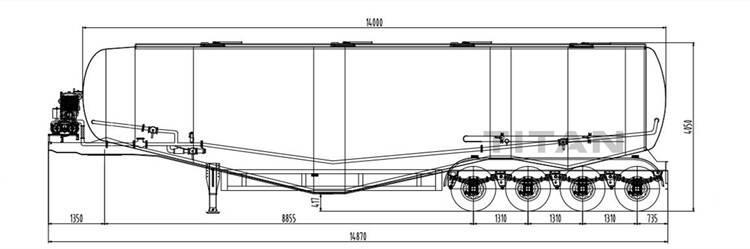

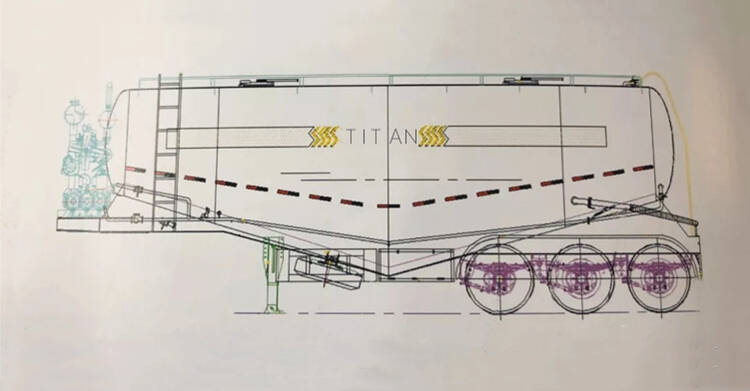

Drawing of cement bulker trailer transporter cement bulker for sale

Model: 3 axles V types bulk cement tankers for sale

Dimension: 9500*2500 *4000mm

Tanker body material: high strength wear-resistance steel

Payload : 30-80cbm(Optional)

Axles:3 axles

Tire:12 units

Application: transport lime, cement, powder etc.

Tank body thickness: 3.5mm

Compressor: 12m3 double cylinder air compressor

Spare tire rack: 2 units

Leaf spring: 10 pieces

Sprinkler: one sprinkler; car waxing

Diesel Engine: WEICHAI Brand

Compressor: BOHAI

Suspension:Heavy duty mechanical suspension

Landing gear:JOST

Brake system: WABCO

Light: LED light (specially intended for oversea markets)

Voltage: 24V

Tool box: 1 set

Painting: Polyurethane paint, with long service lift, and avoid the vehicle get rust

More Technical Parameter Drawings

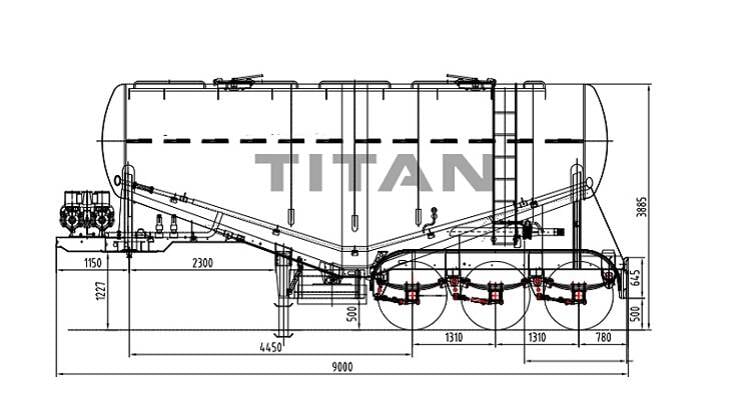

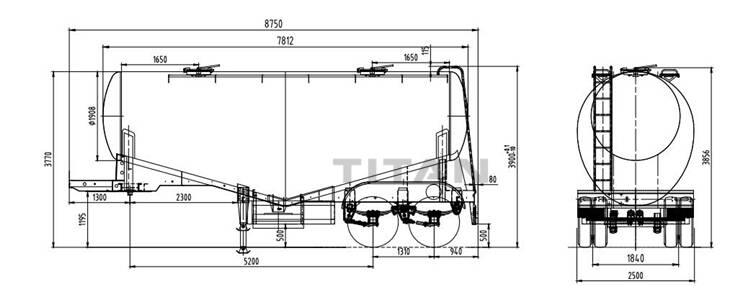

2 axle 30cbm cement bulker price technical specification drawing

3 axle 50cbm bulk cement semi trailer technical drawing

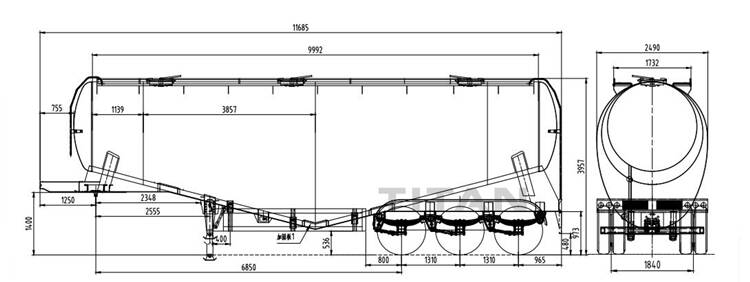

84 cbm 4 axle bulk tanker trailer technical department

In order to prevent the cement bulker truck paint from being corroded by seawater, we spray a layer of wax on the surface of the pneumatic sand trailer before shipping, and then seal it with a waterproof rain cloth.

We will wrap diesel engines of all bulk cement semi trailer with rain cloth.

Package of pneumatic dry bulk trailer

Tank structure: The tank body is made of high-strength alloy steel from a well-known domestic steel plant, which has good performance and reliable welding; the tank body adopts advanced technology to ensure high strength and good airtightness of the tank body; it adopts a throat fluidized bed , Non-side slide structure, gas and material separation device and safe discharge device, effectively reduce the weight of the vehicle and increase the discharge speed.

Power device: The power system can choose the power of the main vehicle, which saves costs and is easy to operate; it can also be equipped with a traditional diesel engine transmission; it can also be driven by a motor to reduce fuel consumption, effectively saving costs for customers, and multiple options to maximize It is convenient for customers to choose a source of power.

Use cast aluminum lightweight material cover: the top cover can be easily lifted with one finger, the fasteners are all galvanized, and the unique design of the material port eliminates the accumulation of materials, which greatly facilitates customer use and reduces maintenance cost.

Use of lightweight materials: aluminum alloy accessories are widely used, such as: aluminum alloy legs, side guards, rear guards, mudguards, outer escalators, integrated detachable anti-skid walking platform, discharge butterfly valve, etc., light structure and operation It is more flexible and convenient, wear-resistant and has a long service life, high-end beauty and safety, while ensuring performance, it has strong corrosion resistance, preventing rust and reducing customer maintenance costs.

Braking system: Double pipeline braking system is adopted, equipped with imported relay valve, pneumatic main vehicle braking system and ABS anti-lock braking system to ensure the safe driving of the vehicle.

Suspension system: The high-strength, light-wearing suspension of a well-known domestic brand is adopted. It is composed of tandem light-weight leaf springs, high-strength tie rods and supports to ensure the load balance of each axle and effectively prevent the phenomenon of vehicle deviation and tire gnawing.

Traveling mechanism: The axle adopts well-known domestic brands, uses aluminum alloy steel rims and tubeless tires, and is reasonably matched to adapt to various road conditions to ensure stable, safe and reliable driving.

Paint spraying: The tank body has undergone multiple processes such as shot blasting, sanding, cleaning, primer, middle coating, top coat, and drying, which effectively improves paint film adhesion. The salt spray test proves that the tank body has strong corrosion resistance.

3 Axles 35m³ Bulk Cement Tanker Trailer has be sent to Zimbabwe Harare

Advanced production equipment can ensure longer product life

TITAN-bulk cement tanker manufacturers powder tanker trailer adopts a three-dimensional design scheme. Three-dimensional design refers to the use of a computer to represent the actual shape of the product as a three-dimensional model, so that the three-dimensional model can contain more actual structural features, and can truly reflect the structure and manufacturing process of the actual product by simulating the product.

At the same time, computer-aided analysis of the structural mechanical properties of the cement bulker for sale tank body, and optimization of the structural performance, make the entire bulk cement tank semi trailer body more reasonable, so that the tank body can have a longer service life.

Painting process and environmental protection are very important

After the external shape and internal structure are designed, the cement tanker trailer tank body needs to be painted. The tank body of 3 axle pneumatic sand trailer adopts spray + powder spraying process design, which can make the coating life 5-8 years without fading.

And the weather resistance and corrosion resistance of the paint used can be doubled compared with ordinary paint. The thickness of the coating reaches H level, which is less likely to be scratched. Finally, the preliminary treatment does not contain phosphorus and heavy metal materials, which is more environmentally friendly.

The interior design of the tank should be professional

The dry bulk cement tanker trailer design structure of the fluidized bed inside the pneumatic dry bulk trailer for sale.

The inclination angle of the barrel and side slide of cement tank truck is greater than 2-3 degrees compared with other bulk cement tank semi trailer in the same industry. This can improve the fluidity of the materials, reduce the residual amount of materials inside the tank and unload the materials as soon as possible. cement bulker for sale can reach 1.5 tons per minute.

The discharge port of the dry bulk cement tanker trailer body also adopts an enlarged design, which can ensure that the material can be supplied adequately when discharging, and the material can be discharged at the fastest speed. Moreover, the reinforced support of the discharge pipe, using the triangular stability principle, can ensure that During the unloading process, the cement powder truck pipeline has no displacement and has the best stability.

Factory of cement silo trailer for sale

Know the capacity you want to transport

This would probably come first in your considerations. How much of cement do you want to transport and for what distance.

If you have a lot of stock to transport, pneumatic tanker truck is important you get a tanker with a high volume capacity and strong enough to manage that weight.

Getting the most appropriate option for your cement capacity will come as a result of a combination of various specifications. You will not just be looking for the volume needs only.

It is important to establish whether the volume provided is fully supported by the construction approach. The durability of the cement silo trailer for sale is also something you need to look at.

Tank production and welding quality

One thing you must understand about pneumatic powder tankers that are commonly used for bulk cement transportation is that they are high-pressure containers.

Therefore, you must ensure that the water tank is strong and strong enough to improve the quality and safety of the operation.

This is a huge investment, so you need to make sure that your money is not in trouble. You don't want to repair it frequently.

Factory of cement bulk tanker trailer

Tanker Thickness

The thickness of the pneumatic tanker trailer is an important aspect to check. It is normally chosen according to the tank’s capacity. There are standards already set in the industry to guide you in making the right choice. Therefore, don’t think that the one with a thicker wall is the best. It must well-matched with its capacity requirements.

The material of Construction

You can choose between stainless steel and aluminum alloy constructions. With a stainless steel construction, your cement bulker truck for sale will not be easily attacked by rust hence can guarantee a long-life.

Bulk Cement Trailer Options to Buy

In your search for a bulk cement tanker, you will come across 3 structures to choose from. There is a reason why these three exists and therefore, it is important to understand that so that you can make the best choice for your application.

Of these three are the funnel, lifting and horizontal structures. Each of these tankers is designed for a particular type of cargo and weight.

china 3 axles 30m3 40 ton v shape cement tanker trailer for sale

china 3 axles 30m3 40 ton v shape cement tanker trailer for sale

The dry bulk cement tanker trailer used for transporting cement is a bulk powder transport vehicle made of a combined specially designed chassis, pneumatic piping system, tanker and discharging units.

This design is specially made for the safe transportation of pneumatic tanker truck commodities, lime powder, coal powder and any other dry powder material that has a particle diameter of less than 0.1mm. Its common application and use are in the cement manufacturing factory, construction sites and the 40 ton cement trailer warehouse. With the use of this type of powder tanker trailer, packaging and discharging costs are greatly reduced.

Simple and Convenient

A pneumatic tanker trailer can transport a lot of cement at once. Most importantly, it ensures that the quality of the cement in transit is safe from any dampening.

No much of packaging and unpacking is needed with the use of a cement tanker trailer. The process of loading and unloading cement from the tanker is simplified through the fluidization process.

High Load Carrying Capacity

The cement tanker trailer takes up to 95 cubic meter capacity per set.

It provides a perfect solution for the transportation of high volumes of cement especially for heavy construction projects unlike using traditional cement transportation means that may not be sufficient for handling large projects.

Effective and Reliable Delivery Speed

The transportation of high amounts of cement can be done at reliable speeds. The trailer offers an effective means of transportation taking up huge volumes of cement at ago.

This saves a lot on transportation costs. Everything is designed to ensure efficient transportation and delivery of large volumes of cement efficiently and in the shortest time possible.

pneumatic tanker trailer for sale

1. Transport materials, wide range

V shape cement tanker truck can transport cement, fly ash and other special materials. Special tank structure is designed to ensure normal discharge. More beautiful and more square The whole pneumatic trailers has a compact design, beautiful appearance, smooth lines, simple and generous.

2. Light weight, high benefit

After a number of software analyses and repeated tests, the 3 axles bulk cement tanker trailer tank body, frame and other structures are made of high-strength steel, and the overall structure of the cement tank trailers' body is more reasonable.

3. Less surplus, high benefit

The vulcanization angle of the tank and the radius of curvature of the cement tank trailers tank is optimized, and the remaining material in the tank is effectively reduced.

4. Safer and more durable

The cement tanker truck tank body is automatically welded by robots, and the air tightness test is performed at 1.5 times the working pressure, which is safer.

5. More loading, fast unloading

At a vertical height of 15m, a horizontal distance of 5m, and a rated working pressure of 0.2MPa, the average discharge speed is greater than 1.3t/min or 1.1m³/min. After testing, in the case of loading and unloading PO42.5 cement, the bulk tank trailers average discharge speed is about 1.5 tons/min.

40 ton cement trailer factory

40 ton cement trailer factory

The main assembly of the pneumatic trailers is composed of a tank body, a power system (diesel engine, air compressor), a gas circuit system, and a brake system.

At present, the design of the fluidized bed in the tanks of general large manufacturers is scientific and the layout is reasonable, which can effectively shorten the discharge time and reach 1.4T / min.

The volume utilization rate of the tank is improved, and the residual ash rate is reduced, and the residual ash rate is 0.2%.

Power system:

Single-cylinder or double cylinder air compressor is used to provide compressed air for discharge work, the pneumatic trailers rated working pressure is 0.2Mpa; the displacement is 10-14 cubic meters/min.

Diesel engine and motor wave can be used to connect and drive through the secondary force device The shaft provides power input for the air compressor.

Tank body:

The 3 axles bulk cement tanker trailer tank body is mainly composed of two oblique cones and front and rear heads. It is placed on the frame and serves as a carrier. The tank body is equipped with a feed inlet, a non-slip walking platform and a ladder for loading and maintenance personnel to enter the tank. The tank has slides, air chambers, discharge ports, etc., and the tank structure is V-shaped 40 ton cement trailer, W-shaped 30m3 bulk cement trailer or straight shape cement tanker.

The v shape cement tanker truck is a single cement tank trailers, generally suitable for designing cubic numbers of 15-45m³. The W shape 3 axles bulk cement tanker trailer is a double-storage bulk tank trailers, generally suitable for designing cubic numbers of 50-75m³.

30m3 bulk cement trailer

Piping system:

Intake pipe: After the gas is output by the air compressor, it enters each cabin through the check valve and the ball valve. A safety valve is installed before and after the check valve to prevent the pipeline pressure from being too high to damage the air compressor in case of an accident. The safety valve is set to bleed pressure to 0.2Mpa.

A pressure relief valve is installed on the top of the pneumatic trailers tank body to release the residual pressure in the tank, and is used for deflation before the user opens the material cover and stops discharging in the middle.

Unloading pipeline:

The discharge pipeline is mainly composed of suction port, butterfly valve, discharge steel pipe, discharge pipe joint, discharge hose, etc.

An anti-shock pressure gauge is installed on the bulk tank trailers tank body to monitor the pressure change in the tank and to guide the discharge.

Bulk Cement Trailer is also called cement transport vehicle, silobas or silo trailer. It is mainly used for the bulk packing of powder dry materials such as fly ash, cement, lime powder, ore powder, granular alkali, aluminum powder, etc. transport. TITAN bulk cement tanker manufacturers often see bulk cement tank semi trailer for the transportation of powdered materials at cement plants, cement warehouses and large construction sites. And bulk feed tankers for sale.

Bulker truck transporter adopts pneumatic discharge, the vertical height of the discharge can reach 25m, and the fastest discharge speed can reach 1.5 tons/minute.

(1) What are the common types of all bulk tankers?

V type bulk cement truck, W type double warehouse bulk tanker trailer and Horizontal bulk cement tanker

(2) What is the tonnage and volume of the cement tanker trailer?

The bulk cement tanker trailer for export to Uzbekistan and Africa are mainly used to transport 30 tons, 40 tons, 45 tons and 80 tons of cement.

The main volumes of silo semi trailer for export to Africa and South America are 25 cubic meters, 30 cubic meters, 35 cubic meters, 38 cubic meters, 40 cubic meters, 50 cubic meters, 60 cubic meters, and 80 cubic meters.

Cement bulker trailer will be tested for airtightness after the production is completed. The tank is compressed to 0.2MPa by air compressor. If the air pressure does not decrease after 12 hours, the next production will be carried out.

If the air pressure after 12 drops, the tank needs to find the welding defects and re-weld, and then conduct the leak test again.

In order to prevent the pneumatic bulk tanker paint from being corroded by seawater, we spray a layer of wax on the surface of the pneumatic sand trailer before shipping, and then seal it with a waterproof rain cloth.

We will wrap diesel engines of all bulk cement semi trailer with rain cloth.

Package of cement tanker for sale with work

Working Principle:

The cement transport vehicle uses its own engine to drive the on-board air compressor, and sends compressed air through the pipeline to the air chamber at the bottom of the sealed tank, so that the cement on the fluidized bed is suspended in a fluid state. When the pressure reaches the rated value, the discharge valve is opened, and the fluidized cement is transported through the pipeline for transportation.

Design Features:

Only by the world’s most advanced manufacturing process, the design is novel, durable. The bulk cement tankers for sale air bag type has a large carrying capacity, fast discharge speed and small residual quantity. The integrated tank body has the characteristics of high overall strength, good rigidity, good pressure resistance.

The fluidized bed in the tank is scientifically designed and reasonably arranged, which can effectively shorten the discharge time to 1.4T / min, which improves the volume utilization rate of the tank and reduces the residual ash rate, which is 0.2%. The tank body of the silobas trailer adopts a double-cone inclination horizontal structure, double-tube intake and double-barrel feeding, and its discharge speed and remaining rate meet the requirements of industry standards.

(1). Before opening the feeding cover, you must open the pressure relief valve and the inlet pipe ball valve to remove the remaining air in the tank before opening the tank cover to avoid injury.

(2). You should always pay attention to whether the pressure gauge is working properly, to prevent the pressure gauge from malfunctioning and overpressure, and the bulk cement tankers for sale bursting.

(3). Always check the safety valve to ensure that the pressure is released at 0.2Mpa, and the pressure inside the pneumatic trailer's tank must not exceed 0.2Mpa.

(4). Often check whether the operation table is working properly, so as not to overrun and damage the air compressor.

(5). Always listen to the sound of power take-off and air compressor rotation. If there are abnormal sounds, stop troubleshooting immediately.

V type silobas cement bulker price

(1). Before unloading, check whether the unloading disc valve, external air source interface, exhaust valve and two feeding ports are closed and tightened. If they are not tightened, tighten them first to prevent air leakage;

(2). Start the engine and shift the transmission to neutral while pressing the clutch pedal to completely separate the transmission from the engine;

(3). Turn on the power take-off solenoid valve switch, and slowly release the clutch pedal to rotate the pneumatic bulk tanker air compressor.

(4). Adjust the control handle of the control mechanism to adjust the speed of the bulk cement tankers for sale air compressor to about 900r / min and stabilize it;

(5). When the pressure reaches 0.18MPa, first open the auxiliary blow pipe, then open the front and rear bin discharge disc valves to start discharging, after which the pointer of the air compressor will stabilize to a certain value;

(6). When the air pressure drops to 0.04Mpa, the back bin has been unloaded. Close the blower tube, open and close the back bin valve several times, and then close the back bin valve and the back bin intake valve. After which the pressure will rise and stabilize to a certain value;

(7). When the cement tank truck pressure of the barometer reaches 0MPa, the discharge is completed, pneumatic dry bulk trailer air compressor is closed, and the discharge disc valve is closed.

Cement bulker trailer factory

(1). Air compressor: According to the instructions of the bulk cement tanker manufacturers air compressor. Be sure to add lube before use!

(2). Engine: Pay attention to regularly check its lubrication and operating conditions. If there is any abnormal noise, the cause of identified and eliminated in time. The gear meshing and wear should check once a year, and it should not run at high speed.

(3). Gas path: The cement tank truck sealing condition should be checked frequently, and if there is air leakage, it should be removed in time.

(4). Tank body: Regularly check the tank body for leaks.

(5). Tank air chamber: Check the air chamber canvas frequently. And check whether the air chamber bead is compacted.

Welcome to leave your v shape cement tanker inquiry!

We will meet the acme of perfection to serve and provide more details, bulker truck price, catalog, drawing, videos for you!