Ten Years of Reliability Your Trusted Partner

The tri axle flatbed trailer is a kind of trailer whose design is suitably made to carry bulk cargo and containers between shipping facilities and terminals.

By simple definition, this is a long flat platform of either 20ft, 40ft, 48ft or 53ft length used for carrying shipping containers. The flatbed semi trailer has no roof or walls to the side.

The size of the container 40 foot trailer loading area is determined according to the standard container size. A twist-lock device for fixing the container is provided at positions corresponding to the four corners of the bottom of the container.

It is carefully designed to desired heights and weight capacity to safely load and transport cargoes from one location to another. Use tri axle trailers to transfer cargo at the shipper’s warehouse. Unloaded to the consignee’s warehouse, when changing trailer or boat on the way, there is no need to take the goods out of the box and change them.

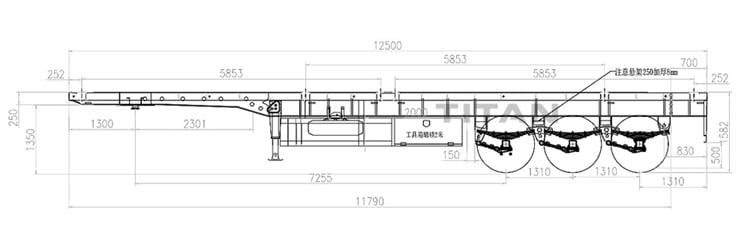

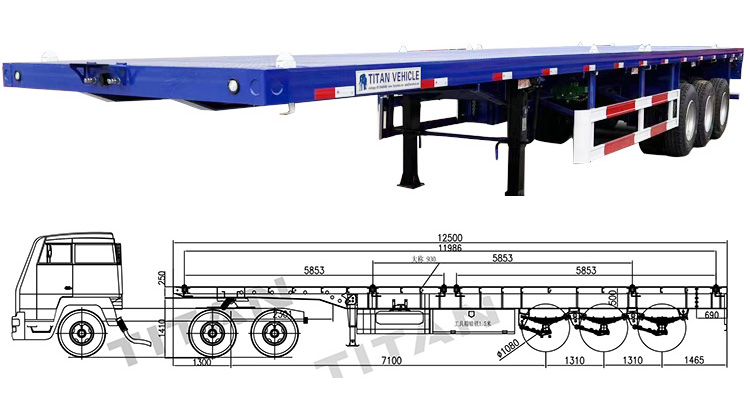

Below is the main specification of the best-selling tri axle 40 ft trailer:

Model: 3 Axle Flatbed Truck Trailer

Transport: 20ft, 40ft container

Overall dimension: 12500mm * 2500mm *1530mm

Capacity: 60 tons

Axles: 3 axles , 13t

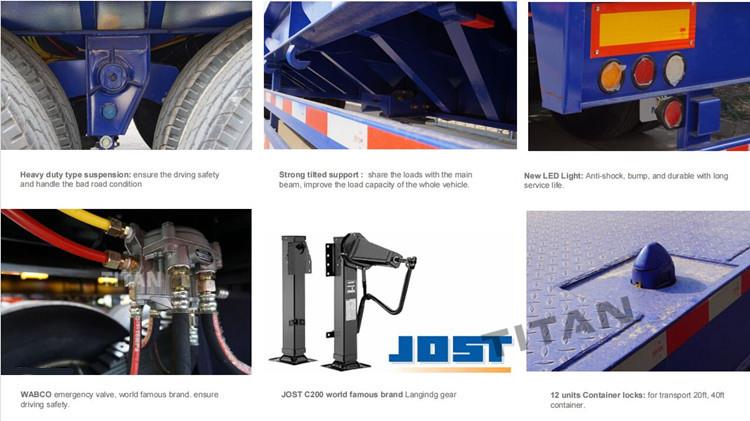

Suspension: Heavy duty mechanical suspension

Tire: 12 units

King pin: 90#

Langing gear: JOST

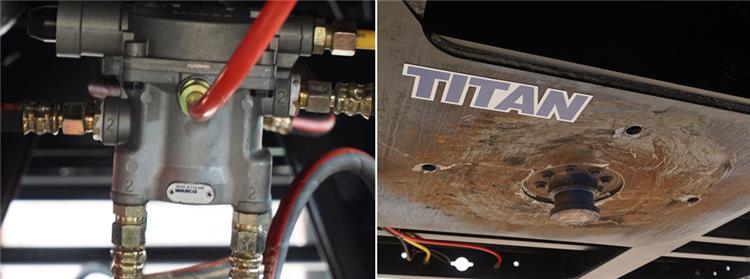

Brake system: WABCO

Electical system: 24V, LED lights

1. Tri axle trailer frame

High strength of high-strength steel: The biggest feature of high-strength steel is its high strength. The yield strength of high-strength steel is twice that of manganese steel and three times that of ordinary steel.

When flatbed trailer manufacturers frame, it bears the same strength. The frame made of high-strength steel uses less material. The upper wing plate, lower wing plate and vertical plate can be made thinner and lighter. Under the premise of charging by weight and standard loading, the advantages are more obvious.

45ft/48 ft flatbed trailer for sale using high-strength steel beams are best suited for the transportation of light-dumping goods with good road conditions and high-speed standard loads. They are not suitable for mountainous, overloaded, and poor road conditions. Overloading is strictly prohibited, especially concentrated loads, and do not privately weld the beams.

2. Flatbed Container Trailer support device

Commonly known as outrigger. Using the principle of "standing timber jacking", it is located at the front end of the 53 foot flatbed trailer for sale frame for use after the container semi trailer is separated from the tractor. Classification of outriggers: Single-acting outriggers are operated separately on both sides, there are two cranks, and each gear has a car gearbox.

Linked outriggers are made from both sides while operating. There is only one crank, which is composed of one gearbox and one without.

The main components of the outrigger are two-speed gearbox, support sleeve, support rod, drive screw, and the support plate. The structure is very simple and the function is very important.

3. Suspension of 40 ft flatbed trailer for sale

Steel plate suspension is our common leaf spring, its full name is series-connected leaf spring balance suspension. It is mainly composed of leaf springs, suspension bearings (commonly known as lifting lugs), connecting rods, U-bolts and other parts. The longitudinal force of the car body falls directly on an axle. The biggest advantage of this kind of suspension is low price, good reliability and easy maintenance. At present, more than 80% of ordinary flat deck trailer in China use leaf spring balanced suspension.

The most obvious feature of 40ft trailer for sale air suspension is its airbag-type air spring. The40ft trailer for sale air spring itself is relatively light in weight, the friction of the air medium in the airbag is small, there is almost no noise during operation, and its life is 2-3 times that of leaf springs. However, when an air spring is used, a rod system that can transmit various forces and moments other than the vertical force must be provided, so the suspension structure is complicated; in addition, the air spring has strict requirements for sealing, and its cost is also high.

4. Braking system

Brake air chambers are round metal containers, located at each wheel, where compressed air is converted into mechanical force to apply the brakes and stop the vehicle.

Brake valve is used to control the braking of trucks or tri axle flatbed trailer. It is suitable for flatbed tri axle trailer with dual-line brake system, and parking or emergency brakes are air-braking brakes. It has the function of automatically causing the 20 ft flatbed trailer brake when the control pipe connection of the trailer brake system is broken or leaking.

5. Tri Axle Trailer Kingpin

The 90 # traction pin represents the diameter of the traction pin is 90mm, and the material is mainly chromium alloy. The flatbed trailers for sale near me and the tractor are all connected by it. It is connected to the traction seat of the main vehicle and also bears all the traction. It is an important component.

At present, the traction pins on the market are mainly divided into 4 types, assembly 50, assembly 90, welding 50, welding 90, users should choose according to different models and actual use.

As a professional manufacturer, TITAN have provided many kinds of semi truck flatbed trailer for sale for many countries, we have much more advantages in the tri axle trailer for sale near me cost and quality control. All semi truck flatbed trailer for sale will undergo rigorous testing before delivery to ensure the quality. We have professional technicians to operate. In addition, a layer of wax will be sprayed on the 40 ft flatbed trailer for sale near me to prevent seawater erosion, and then a layer of rain cloth will be wrapped to prevent moisture so that it is foolproof.

The agent from Nigeria purchased 10 units of tri axle trailer. In fact, the customer bought a tri axle flatbed trailer of his own in 2020. The customer is very satisfied with TITAN’s tri axle flatbed trailer. Many local customers have seen the customer’s semi trailer. He said that he helped purchase at TITAN, thinking that many local customers did not understand the import process. In the next year or so, customers gradually became TITAN's agents.

The quality of the semi trailer and the service of our sales manager Barry have exceeded his expectations. Customers also said they would recommend friends to buy TITAN semi trailers.

The function of a tri axle trailer for sale is made possible through its structure’s design and manufacture. Basically, it is a transport equipment mainly of a steel construction defining its frame. It also comprises a lighting system, brakes and tires. It is carefully designed to desired heights and weight capacity to safely load and transport cargoes from one location to another. Use flat deck trailers to transfer cargo at the shipper’s warehouse. Unloaded to the consignee’s warehouse, when changing trailer or boat on the way, there is no need to take the goods out of the box and change them.

The size of the tri axle flatbed trailer loading area is determined according to the standard container size. A twist lock device for fixing the container is provided at positions corresponding to the four corners of the bottom of the container. Flat deck trailers are special trailers for transporting containers.

The different types of tri axle flatbed trailers are designed for use in different applications. Therefore, it is important to assess your needs before making a choice of the type of flatbed trailer you need. Here are key factors to consider:

Size: The Flat bed trailer is designed to carry different cargoes and containers: a flatbed for a 20ft container and another for a 40ft. If you need a triaxle flat bed for carrying an oversize load, then an extendable flatbed trailer will be the best choice to go for. The choice based on size is usually made putting these requirements into consideration.

Load Capacity: The load capacity can also determine the type of trailer that you will choose based on your needs. It can range from 10 tons – 80 tons. Again, this should be based on different requirements as defined by the local laws and regulations on such matters. The various tri axle flatbed truck trailers take a considerable size and weight of cargo. However, all are not designed to carry the same amount of weight. On applications where weight considerations are to be made, the 2 axles or 3 axles container chassis trailer can really help. Heavy cargo can comfortably and securely be carried on these strong chassis made of high-yield materials.

Axles and Tires: The different axle capacity is based on transportation needs and requirements. However, every choice based on the axle configuration should also be in line with the local transportation laws and regulations. The most common configuration is triaxle flat bed trailer, it comes with 12 tires.

In 2023, TITAN launched a new tri axle flatbed semi trailer. The main purpose of the new tri axle flatbed semi trailer is a trailer designed to transport bulk cargo and containers between shipping facilities and terminals.

The loading capacity of the new 40ft trailer for sale is greatly improved, and it can carry a weight of up to 75ton. In terms of design, the rear tail design of the 2023 model is also a highlight, which is more generous, simple and elegant than the design of the 2022 model.

1)Tri Axle flatbed are primarily used for hauling heavy loads. Multiple axles and wheels allow for better weight displacement and stability.

2)Tri axle flatbed trailer for sale in Nigeria configurations are also used for heavy trailers. For example, since heavy equipment used in construction cannot operate on public roads, it must be towed to the job site using a high-capacity flatbed trailer.

3)The tri axle flatbed semi trailer configuration is smaller and lighter. It can better transport containers or other heavy cargo.

4)One of the main advantages of choosing a triple axle trailer is the load it carries. With better strength, this trailer helps to carry greater capacity than single or double axle trailers.

5)The tri axle trailer for sale in Nigeria also provides better traction through the tri axle

The tri axle trailer for sale container lock is mainly used to fix the container on the container flatbed of tri axle trailer.

International common container specifications are: 20-foot container (8x8x20) and 40-foot container (8x8x40).

In recent years, 40-foot and 45-foot containers have been used more and more. According to the different specifications of the container, the container is equipped with a corresponding number of twist locks.

A standard 3 axle 40ft trailer for sale is usually equipped with 12 sets of locks. A container transport vehicle can be equipped with the same twist lock, or several twist locks can be used in combination, but no matter what form is used, the purpose is to ensure that the container is tightly connected during transportation.

1. Some of container locks tri axle trailer are directly welded on the body, and the lock head can only rotate but not move longitudinally. This is called a fixed type;

2. It can not only rotate, but also extend vertically. When not in use, the lock head can be lowered below the load-bearing surface, which is suitable for different standard box types. This is called the lifting type; it can be moved, and the fastening position can be adjusted, which greatly improves the utilization rate of the tri axle trailer;

3. There is also a plug-in twist lock, the lock shaft extends into the fixed part of the box like a bolt, and is generally used in conjunction with other types of twist locks.

Flatbed trailers are commonly used to transport a variety of goods, equipment, and vehicles that cannot be loaded into closed trailers. Here are several ways to transport flatbed trailers:

1. Towed by a truck: The most common way to transport a tri axle trailer is to have it towed by a truck. The tri axle trailer for sale is hitched to the back of the truck, and the truck drives with the trailer in tow. This is a simple and effective way to transport flatbed trailers over short and long distances.

2. Loaded onto a low-loader: Tri axle trailer for sale that are too large to be towed by a truck can be loaded onto a low-loader for transport. The low-loader is a specialized truck that has a very low platform and is designed to transport oversized and heavy loads. The tri axle trailer for sale is loaded onto the low-loader and secured in place with straps or chains.

3. Transported by train: Triple axle trailer can also be transported by train. This is a cost-effective and environmentally friendly way to transport large numbers of triple axle trailer over long distances. The trailers are loaded onto flatcars, which are specially designed railcars with a flat deck.

4. Shipped by sea: Tri axle trailer can be shipped by sea to transport goods and equipment to other countries. The trailers are loaded onto a shipping container or a roll-on, roll-off (RoRo) vessel, which is a specialized ship designed to carry wheeled cargo such as cars, trucks, and trailers.

5. Air freight: The tri axle trailer for sale can also be transported by air freight for urgent or time-sensitive deliveries. The trailers are loaded onto a cargo plane, which is equipped with a cargo hold large enough to accommodate them. Air freight is the fastest way to transport flatbed trailers, but it is also the most expensive.

The amount of weight that a triple axle trailer can haul depends on several factors such as the size, weight capacity, and construction of the trailer, as well as the weight capacity of the towing vehicle and any applicable weight restrictions or regulations in the area where the trailer will be used.

In general, triple axle trailers are designed to haul heavy loads, and can typically carry anywhere from 40 to 60 tons or more, depending on their size and weight capacity. However, it is important to note that the weight of the cargo should be distributed evenly across the trailer, and that the total weight of the trailer and its contents should not exceed the maximum weight capacity allowed by law or recommended by the manufacturer.

Before using a triple axle trailer to haul heavy loads, it is important to carefully consider all relevant factors, including the weight of the cargo, the weight capacity of the trailer and towing vehicle, and any applicable weight restrictions or regulations. It is also recommended to consult with a qualified professional, such as a trailer manufacturer or experienced truck driver, to ensure that the trailer is being used safely and correctly.