Ten Years of Reliability Your Trusted Partner

The industrial production of chemical sulphuric takes place around the world. However, these acids for instance, would need to be transported to various destinations across the globe. Transport is very important when directing the flow of products to customers.

Some means of transport for acids would therefore require specialized packaging more than other types of goods. The storage and transport of acids has increased through advances in technology and production.

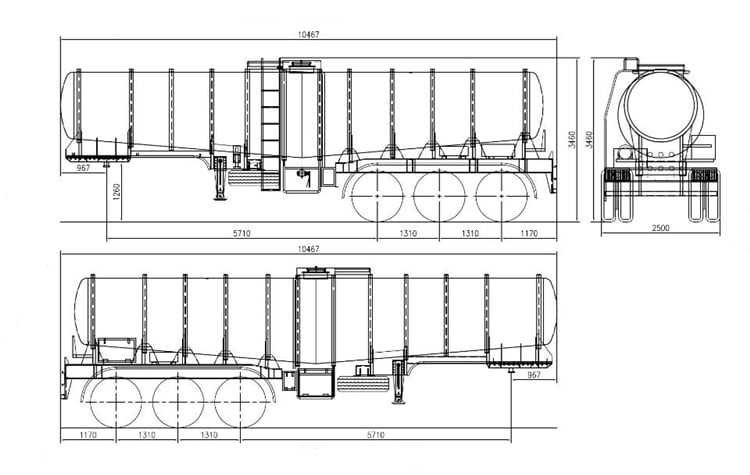

In this guide, we show you designs and details of acid tanker trailer.

The chemical sulphuric tanker trailer is used for transporting different kinds of acids such as: sulfuric acid, hydrochloric acid, hydrofluoric acid, Nitric acid and Acetic acid among others as used for different industrial applications.

Acid Tanker Trailer produced to transport the chemical liquid with a single compartment, 5,000-gallon sulfate transportation solution.

Acids have different chemical and physical properties. In that case, different acids need different materials for the construction of their specific tanker. Chemical liquid transport semi trailer has different requirements for tank material depending on the characteristics of the medium being transported. Common chemical sulphuric tanker trailer materials are stainless steel, carbon steel, aluminum, etc.

TITAN 20000liters acid tanker trailer in factory for sale

About Chemical sulphuric tanker trailer

The inside and outside of the tank are treated with fine anticorrosive paint. With no joints, no leakage, corrosion resistance, aging resistance, impact resistance, long life and other characteristics, it is suitable for storage and transportation of most acids and hydrochloric acid. Operating temperature: -20 ℃ ~ 60 ℃.

For the sulphuric acid tanker, TITAN produce the most strong acid tanker body to make sure the safety. We adop 5mm thick steel to weld the tankers, also use special design, like the 10 pcs strengthened steel ring to reinforce the Dilute Sulfuric Acid tanker trailer.

To keep the chemical sulphuric tanker trailer safety, we use the stainless steel emergency bottom valve also the discharge valves, this type is anti-corrosion, so it can make the chemical tanker trailers to have long service life.

TITAN Vehicle has strong technical force, and can design and manufacture products that satisfy customers.

Customer visit for TITAN acid tanker trailer

The hydrochloric acid tanker trailer is made of a multilayered structure, with the outer part made of either stainless steel or an aluminum alloy.

In most cases, stainless steel has been the main structural material used for these types of tanks. Steel is prone to just a few products that are mostly acid.

However, stainless steel is resistant against dilute sulfuric acid and dilute hydrochloric acid. For this reason, these acid tankers made of stainless steel cannot be corroded.

TIATN Chemical Tankers Trailer for Sale

Why stainless steel is better

It is unlikely that steel would contaminate products and if it does, only a few like high quality caustic soda. Steel is an alloy of iron and carbon hence it is prone to attack by rust.

Rust would cause many problems of contamination of these acids if steel was used to make the structure. Owing to this fact and among other reasons, it is unlikely that steel could be used in the construction of chemical tanker trailers of this nature.

Stainless steel is resistant to chemical activity hence cannot be easily corroded away by substances like dilute sulfuric/hydrochloric acid. Stainless steel characteristics are due to the forming of a very thin, passive chromium oxide layer on the surface that prevents further chemical action on the metal alloy. This protective film remains intact hence no corrosion can take place in such conditions.

It is true that acid tank trailers can’t be corroded. However, there are standard safety checks and procedures that should be carried out for all chemical tank trailers.

The long-term corrosion effect in steel chemical storage tank is the continued thinning of the tank wall section, especially at lower levels. This leads to imperfections of the shell.

The service life of these storage tanks is normally estimated to be in the range of about 20-40 years. To guarantee the safe operation of storage tank, the thickness of the tank should be tested once at least every two years, and every five years for an internal inspection at least.

There are quite a number of damage mechanisms that can cause the deterioration and failure of a storage tank. For this reason, these checks are important to assess the condition of the initial tank surface quality needed to prevent this deterioration.

Corrosion is a prime cause of steel tanks’ deterioration and on their accessories too. While stainless steel tanks are resistant to attack, its continued use and exposure to different environments can make they susceptible to corrosion attack.

Attacks through corrosion are rarely uniform. There at times can be random or localized pitting corrosion attack, especially in flat-bottomed tank floors. The acid temperatures are a contributory factor to this. The tank construction materials and their condition in addition to their durability and effectiveness of the base seal among other factors play a part in the corrosion resistance nature of the acid tanker trailer.

If you want more information about our semi-trailer, please click “Sulfuric Acid Tank Trailer“.

And you can also look at other articles and videos on our website.