Ten Years of Reliability Your Trusted Partner

Now there are more and more semi-trailers running on the road. Many users engaged in long-distance transportation have chosen semi-trailers. But do you know how to make a lowbed trailer? Today, I will take you to TITAN trailer production workshop in the form of pictures.

Before production, TITAN technical department must first design and produce drawings according to the needs of the user and the market, so that the technical parameters of the main trailer are matched, and then transferred to the manufacturing department.

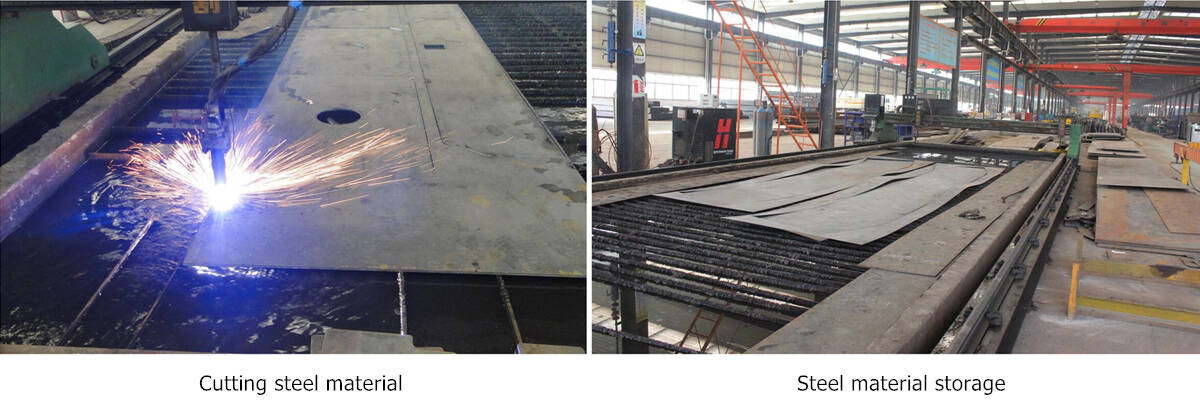

According to the drawings of each part produced by the design department, each part is cut out with a CNC cutting machine, such as beam webs, reinforcement plates, standard small accessories and so on.

The second step is to fix the cut web and the upper and lower wing plates to weld points, and then weld the beam by submerged arc welding.

This step is very important. Both the fixing of the beam and the submerged arc welding are very demanding. If the technical process is not feasible, the beam will have problems. Can the trailer be okay if something goes wrong?

TITAN gooseneck lowbed trailer front neck bend

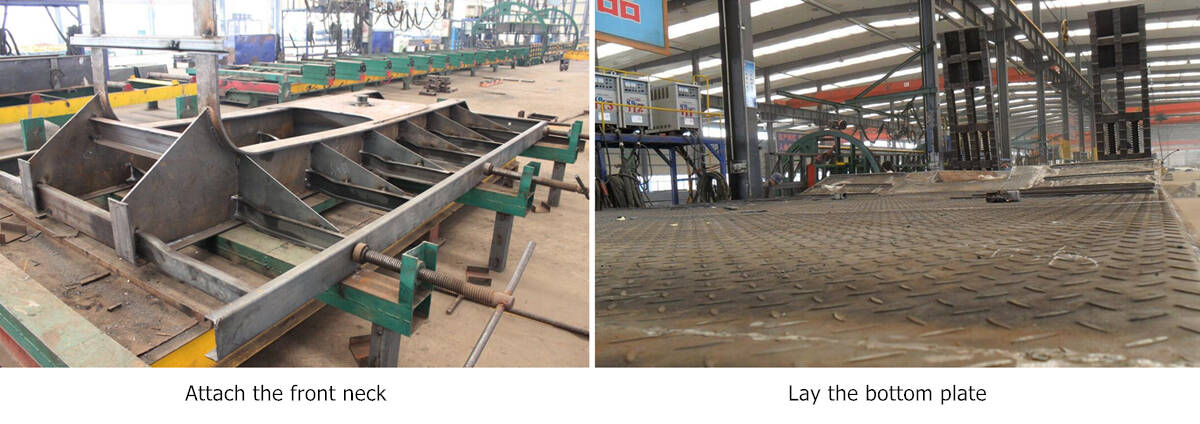

First cut out the web of the beam to cut out U-shaped holes through which the beams can pass, and then fix the welded I-beams in parallel. The result of comparing the beams is very important. If two I-beams have large parallel errors, very serious tire wear will occur.

At this time, the main beam is basically formed, only the side beams are welded to form the frame structure. And the traction pin traction plate is welded to the position required in the contract, the welding process is required to be high, otherwise the lowbed semi trailer will be skewed.

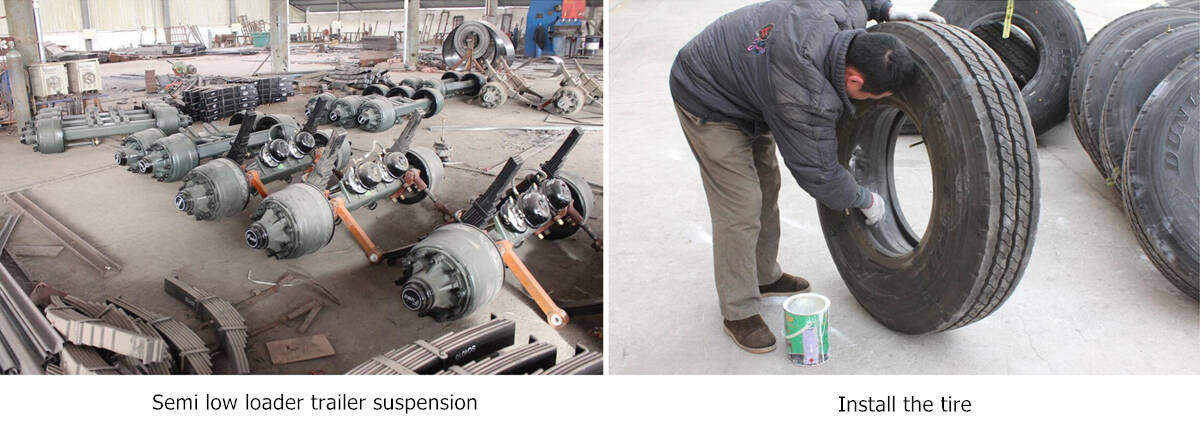

At this time, the welding suspension must strictly control the size and maintain the squareness, otherwise it will cause tire wear.

Low bed semi trailer with front neck have this process, and flatbed semi trailer do not have this process. The front neck of the low bed trailer is welded up. Welding is done to strengthen the plate. There is no problem with the strength. TITAN have also considered it in advance.

That is, the bottom plate is fully welded on the frame. There is nothing to say at this step.

Frosting is the previous step of spray painting. Some manufacturers without shot blasting workshops will blow and polish the welding slag with high pressure gas at this stage.

Spray paint is usually sprayed in a well-ventilated shed. If you want to spray beautifully, you must first look at the coating and the technology of the technicians, but TITAN will spray very beautifully. Basically, you don’t have to worry about this. We will be very attentive!

This 3 axle lowbed trailer is so beautiful after spraying

After spray painting is completed, the bottom travel system is installed, and the assembled bottom is simply mounted and then precisely adjusted.

Everyone is familiar here. It should be noted that the air pressure at the factory is generally not the standard air pressure. You must confirm it again after you buy the trailer.

TITAN have professional staff to make package, all of them were trained constantly. Please notice that to prevent the low loader trailer paint from being corroded by seawater to we spray a layer of wax on the surface of the lowboy trailer before shipping.And covering poncho to prevent from the damp condition.

Seeing this, I believe that everyone has a general understanding of how trailers are manufactured. Choose TITAN can guarantee the quality of the trailer from the manufacturing process.

1. Main beam adopts HG high strength steel, with high loading capacity.

2. Main beam adopts submerged arc welding technology, that ensure the smooth, sturdy welding seams and avoid welding-opening problems. And also improve the loading capacity.

3. The loading ramps is made by high strength steel, with high loading capacity, will not happen to the deformation when carry heavy equipment.

4. The suspension ensure its have high loading capacity, and increase its capacity to twising forces, shock, bump.

5. World famous brand spare part, ensure high quality and save costs.

Through this video below, you can learn about different types of lowbed semi-trailers, like 2axle, 3axle, 4axle lowbed semi trailer, hydraulic ladder lowbed semi trailer, etc.

As well as the process, testing, packaging and customer feedback, etc.

If you want more information about our semi-trailer, please click “Lowbed Semi Trailer“.

And you can also look at other resources and products on our website.